Building a printer: Day 5

This has been.... A journey...

I have submit for, and gotten, a serial number! I am now the proud owner of VS.288 and yes, the audio quality is bad, but I have no clue how to use Davinci Resolve.

Trials and tribulations

This has been both easier than expected, and an absolute nightmare. I've worked with klipper before, but this was my first printer built from scratch, and it shows. I had massive issues with microfit connectors, so things like toolhead wiring is all soldered, and countless other issues here and there, but it works, and it works fast. I've modded the printer a ton from the kit that it started as. I'll try to list the mods here, though it's not exhaustive. I'm sure there are things I've missed.

-

Dragon hotend swapped in

-

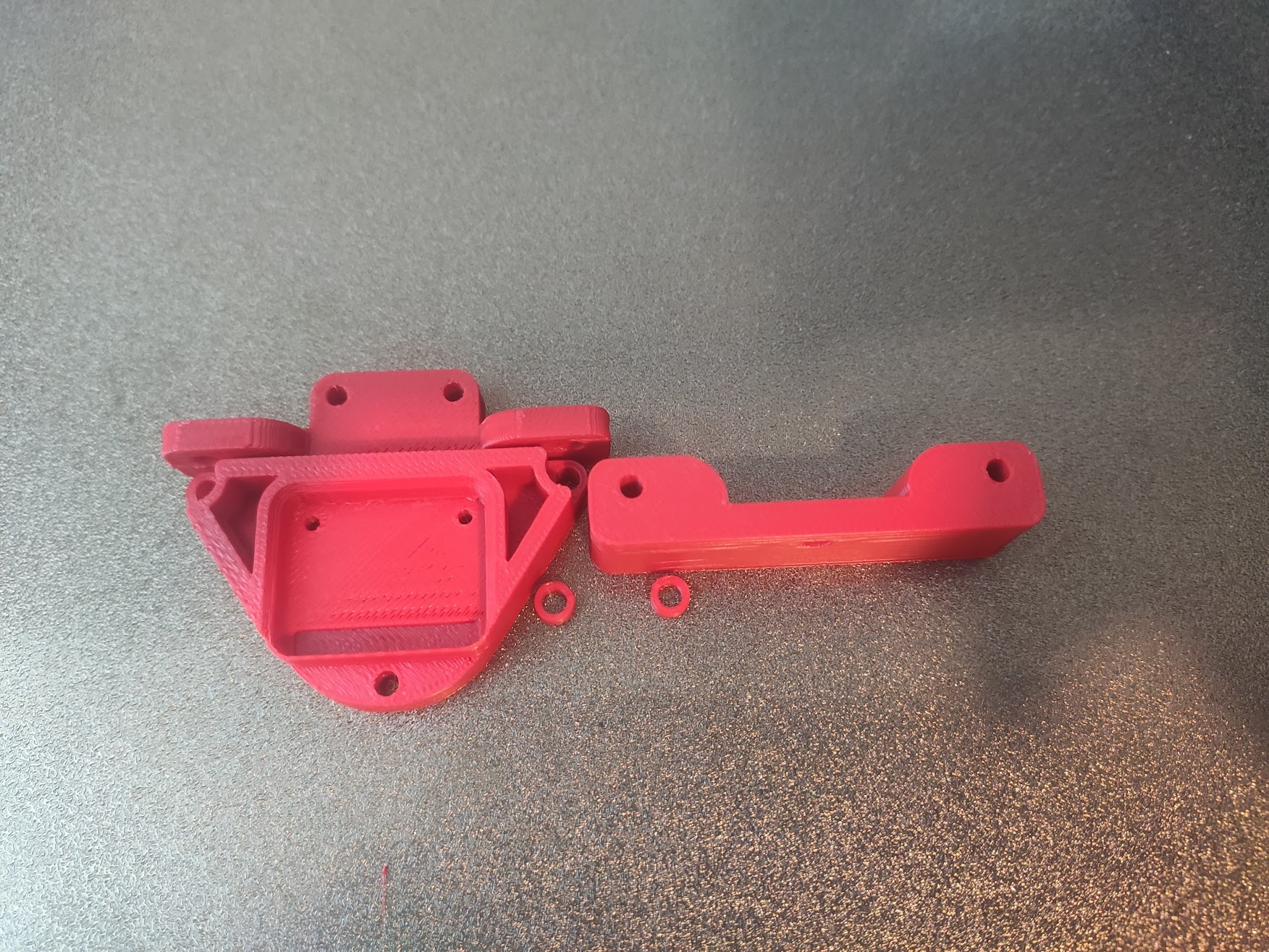

Y belt tensioner mod because stock it was impossible to get correct, and even new belts had to be ordered to fit this mod in.

-

AB-BN It's no secret that Voron designs are built for ABS. I've upgraded the cooling to print materials like PLA better, and it looks so much nicer.

-

Fan mount There's already too much tape in the enclosure, so mounted the fan with a proper mount for the under side.

-

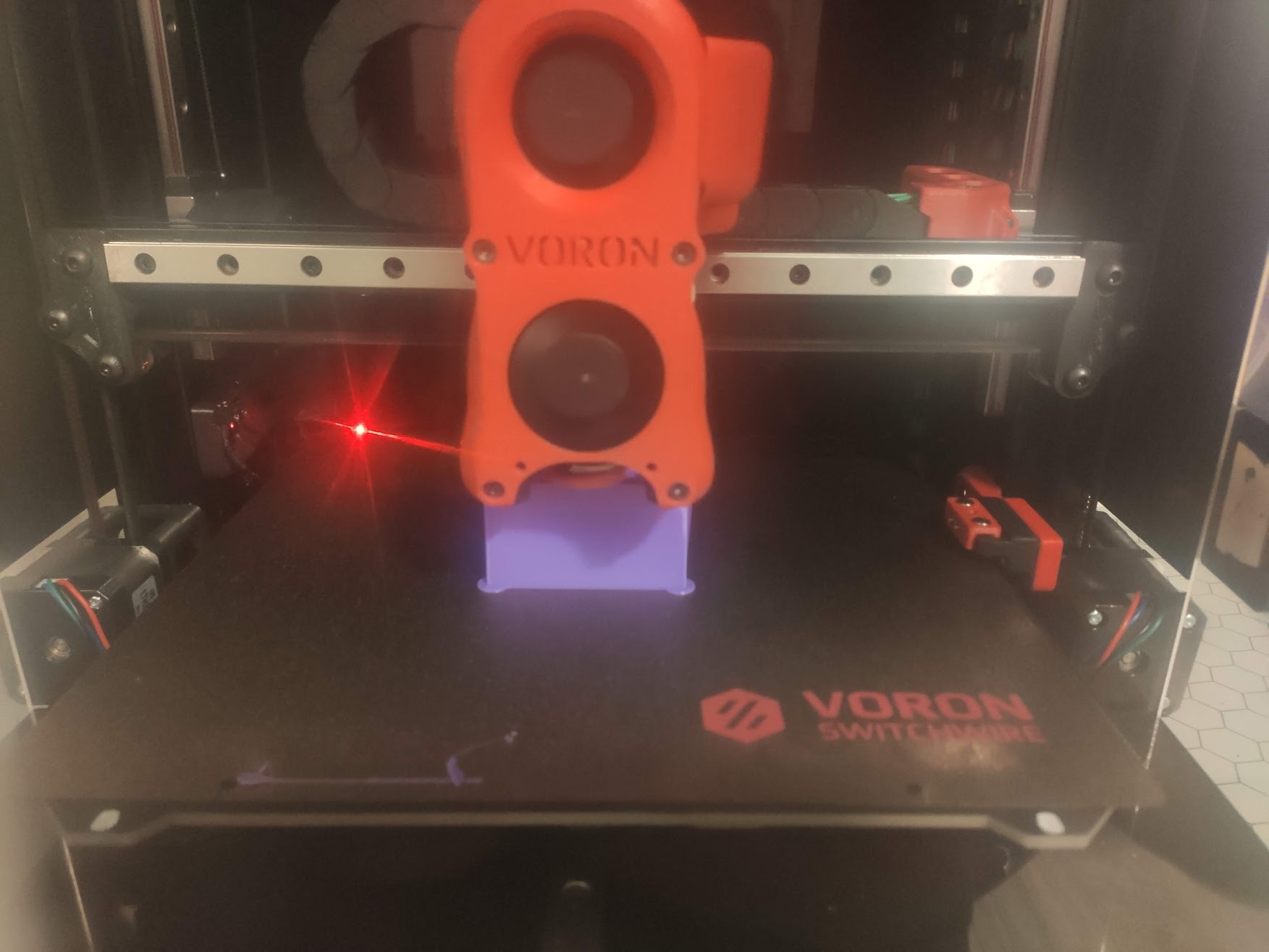

Quickdraw probe not seen in video as it was installed over the last few days after the serial video. It should get more accurate results for a better bed mesh, and isn't prone to drift with heat. Something I'm told hotends get is hot, so that seems like a bad mix with inductive probes.

-

STM32_Mini12864 Added a display because I could. It has no use, but it sure looks cool. This made it easier to wire up considering how little I care.

Where I'm at now

Print quality is nothing short of great considering the speeds, and I'm still in the process of tuning. I've added a port to connect an ADXL345 accelerometer that sits on the bed and the toolhead to measure resonance and compensate for it in firmware due to the speeds that I push.

Speeds and accelerations

; ACCEL: 2000/2000/8 for First Layer

; ACCEL: 7000/7000/8 for Travel

; ACCEL: 1000/1000/8 for TYPE:External perimeter

; ACCEL: 2000/2000/8 for TYPE:Overhang perimeter

; ACCEL: 2000/2000/8 for TYPE:Internal perimeter

; ACCEL: 2000/2000/8 for TYPE:Top solid infill

; ACCEL: 4000/4000/8 for TYPE:Solid infill

; ACCEL: 5000/5000/8 for TYPE:Internal infill

; ACCEL: 5000/5000/8 for TYPE:Bridge infill

; ACCEL: 5000/5000/8 for TYPE:Internal bridge infill

; ACCEL: 2000/2000/8 for TYPE:Thin wall

; ACCEL: 2000/2000/8 for TYPE:Gap fill

; ACCEL: 5000/5000/8 for TYPE:Skirt

; ACCEL: 5000/5000/8 for TYPE:Support material

; ACCEL: 5000/5000/8 for TYPE:Support material interface

Resonance is being handled in software, allowing even a bed flinger to run quite fast as seen in the video above to result in amazing quality, and blazing fast print times. The serial video cube printed to voron spec in 2h31m45s coming in at a massive 57g and 60mm in all dimensions. I'm still not quite happy with the results, so I'm going through this amazing print tuning guide, and dialing in results. There may be room to increase print speeds a bit more here and there, but I'm already maxing out the hotend currently on infill, and with anything higher than a 0.4mm nozzle, so I'll have to go high flow heatbreak, and/or CHT nozzles to get more speed for big parts if I so choose.

What's next?

I've got a lot of tuning to do still, but want to get into some more advanced materials. TPU, PC-Nylon's and anything this printer can print to see what all is possible. Multi colour prints are also on my radar, but I'm sorting through the mess of options for that before I really decide on what I want on that front. I'm waffling on building a V0.1 as well to have a printer than can just print parts stupid fast so I don't have to keep a million spares on hand as well, but undecided if I want to go that route, or just save up for something bigger, or if the Prusa mini is good enough. Only time will tell on these things it seems.

Random things I've printed on the Switchwire

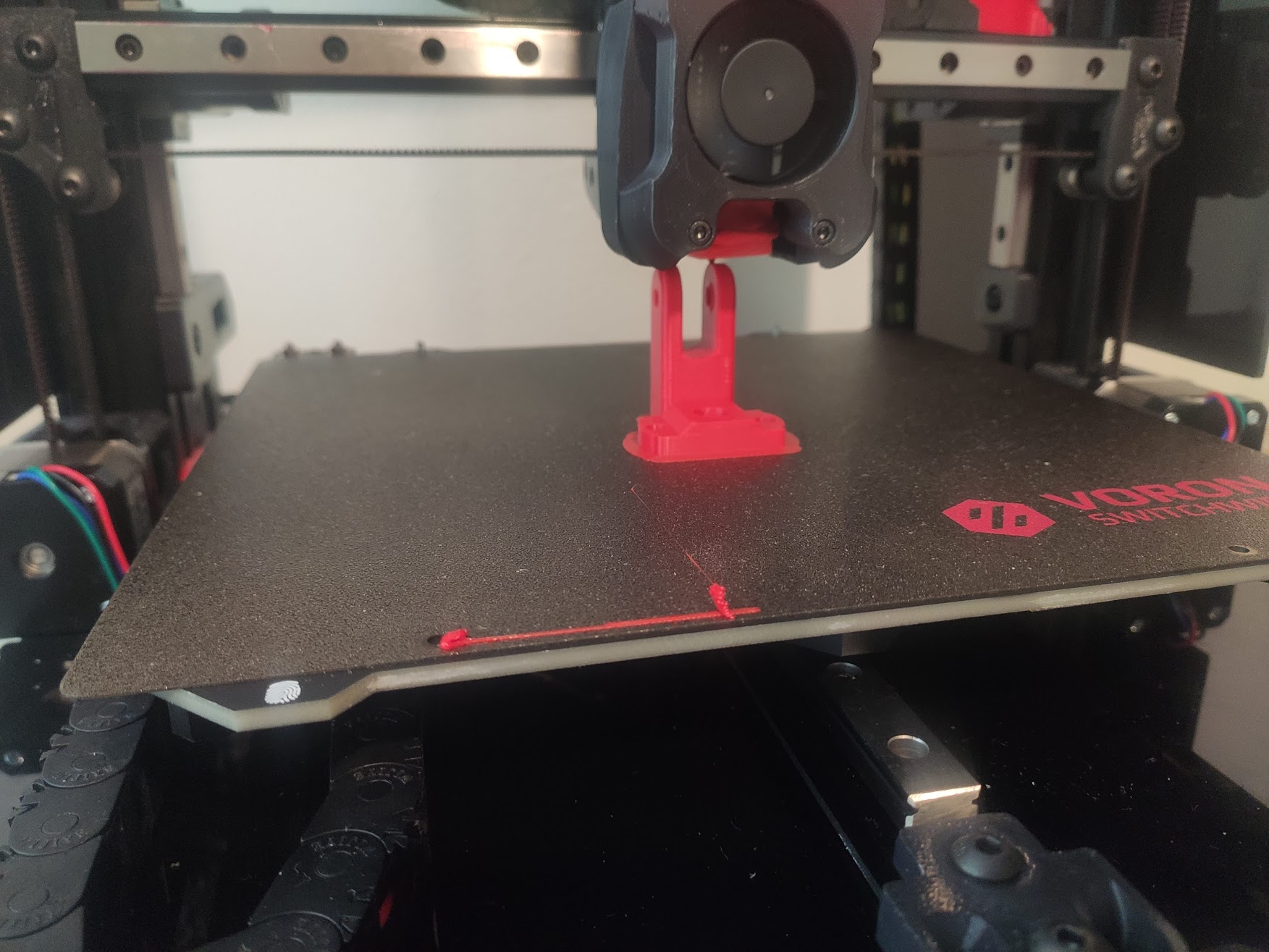

Belt tension mod

Holder for ADXL345

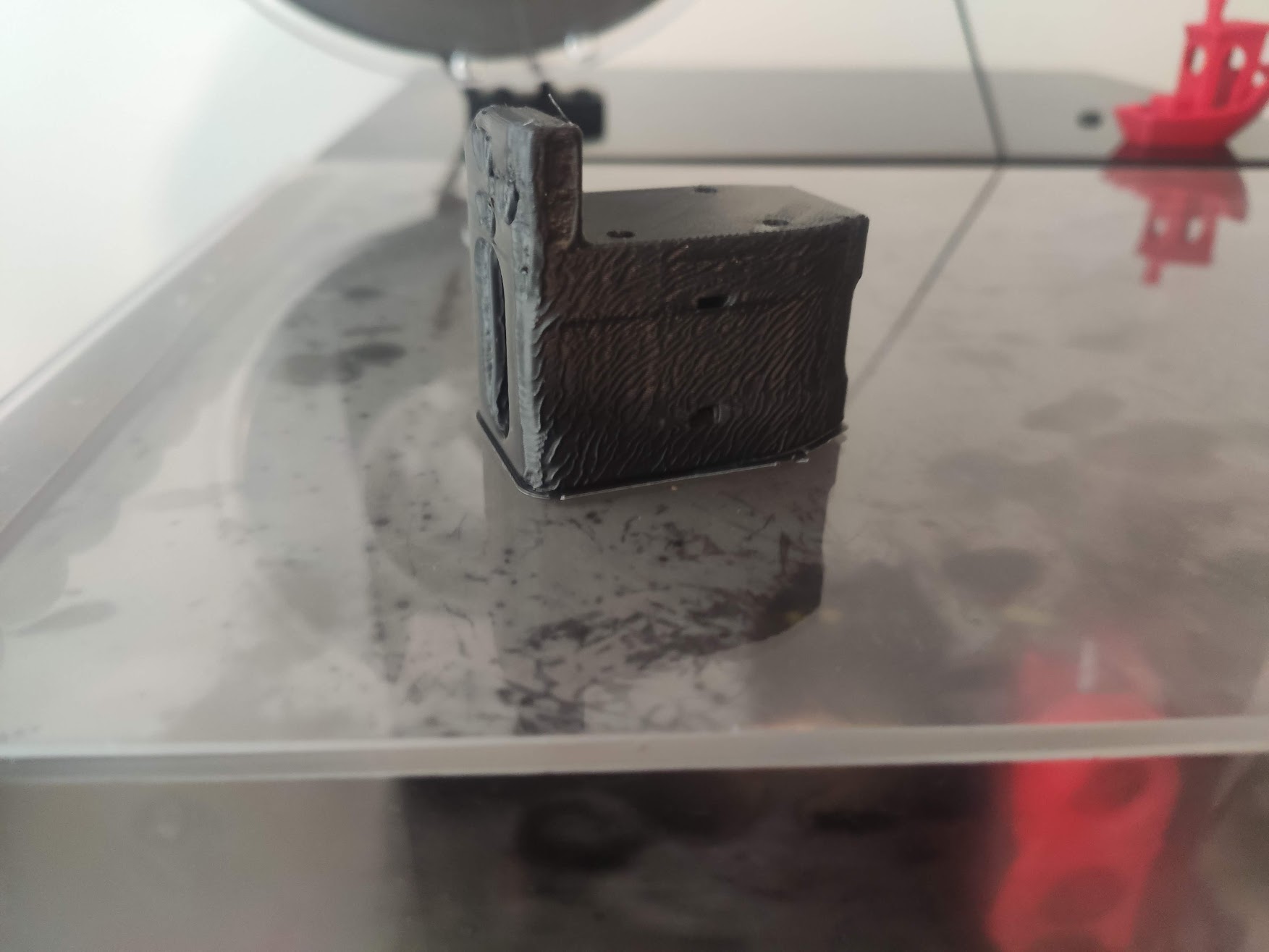

Input shaper tuned wrong

Bed flingers one downside, high accel doesn't go well with thin tall objects

Keycap printed in less than an hour. Looks as good as the one on the prusa mini that took 3.5 hours.

Foxes are cute, so I printed one to do a detail check

Printing a tuning tower for pressure advance. The QuickDraw can be seen in this image finally.

Afterthoughts

While this isn't "done", I don't think it ever will be. I'm not trying to sell anyone on anything here, but if you do happen to need something printed, and can't print it because of lack of print space, or material incompatibility or just don't own a printer, feel free to reach out. I'm sure I could squeeze in some time for you to get your cool idea made, or even just something you want at a cost that's reasonable. I have a really fast printer that's able to print some amazing things, so I'd rather share that with others as opposed to hog it all for myself.