Gotta go... smol?

Time for a teeny tiny printer!

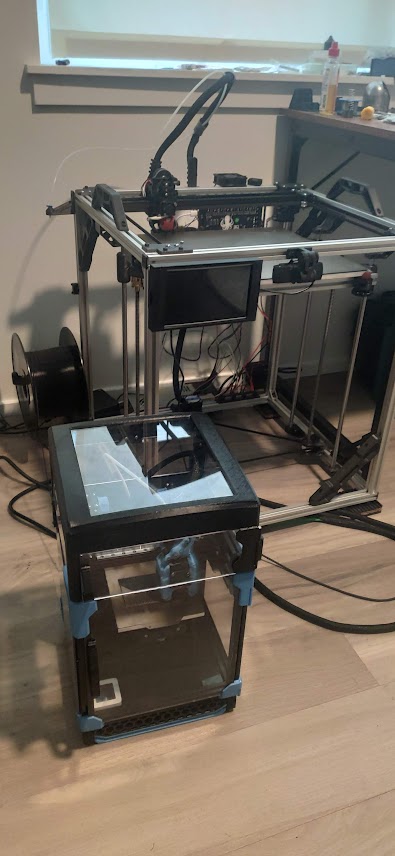

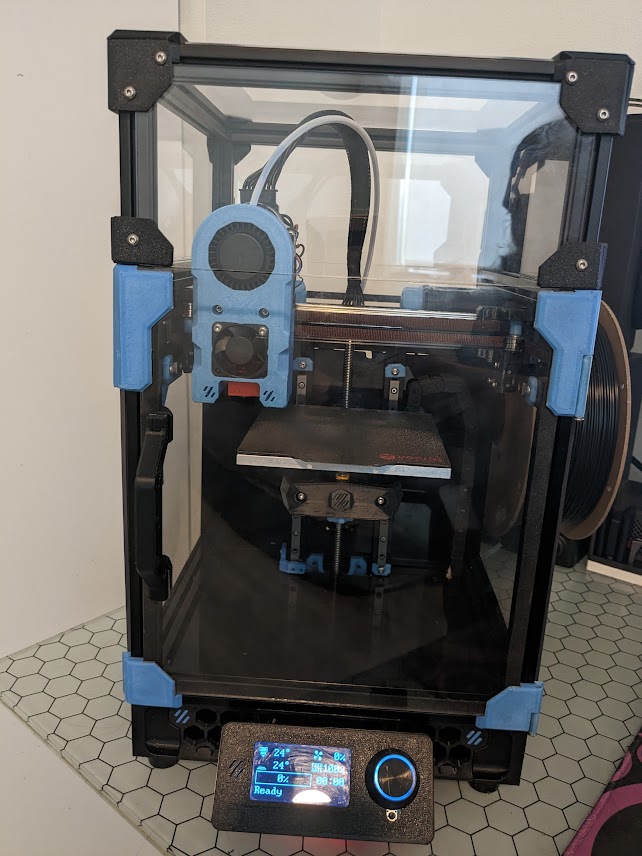

While I absolutely love my Vz330, I have learned some lessons about what it's good and bad at. It's absolutely not a bad printer, and is by no means going to be surplanted any time soon. Sometimes I do feel the need to have a backup printer for when it's down, especially if I need a part that's not already printed. With repraps, you always want a spare printer. In comes the Voron V0! It's got a laughably small build volume, but it's enough to print basically any required part on any 3d printer I own, have owned, or will own. That makes it quite the useful little printer even if some parts I want to print don't fit on it. Enough rambling in an intro, let's see how it went!

The build

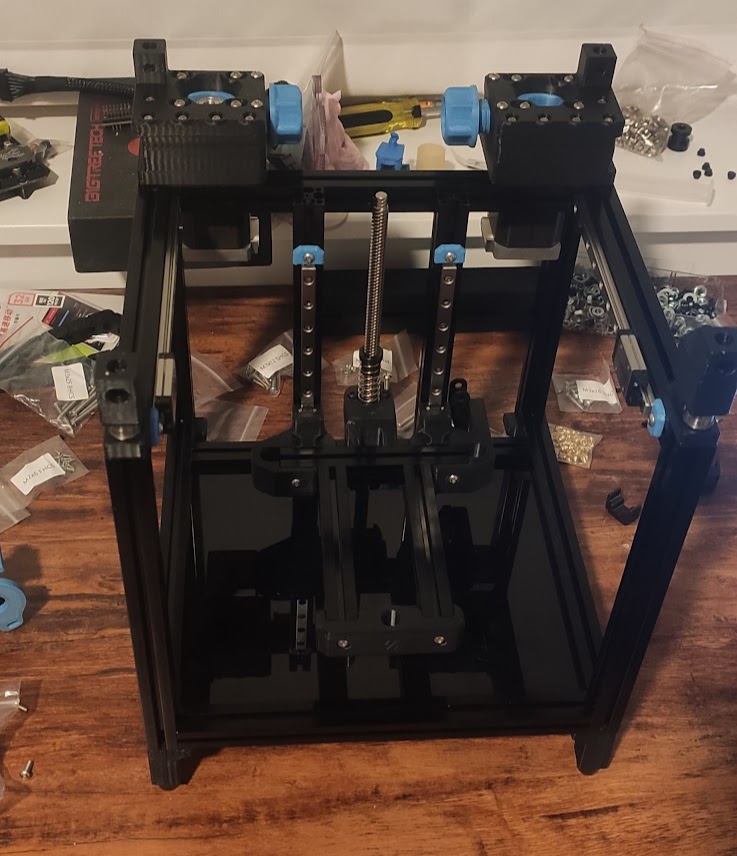

Day 1: Build summary

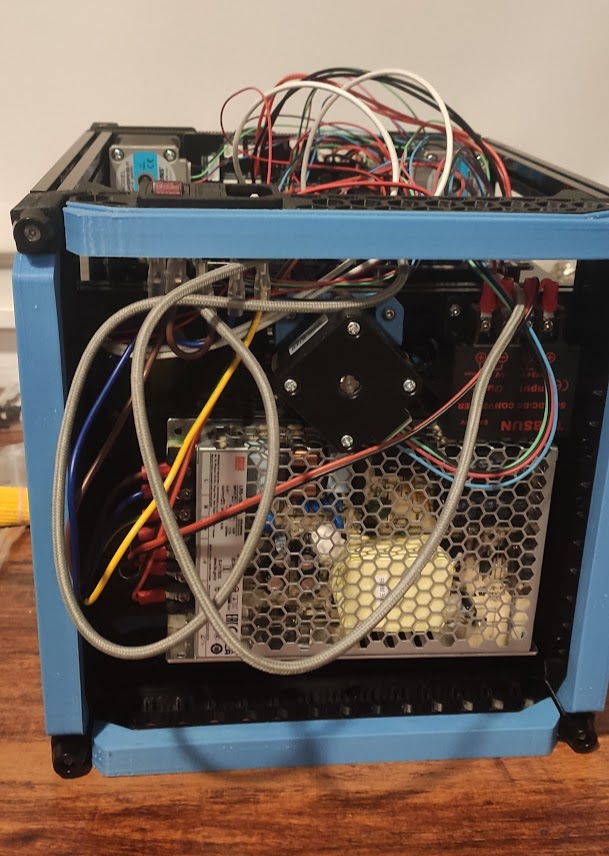

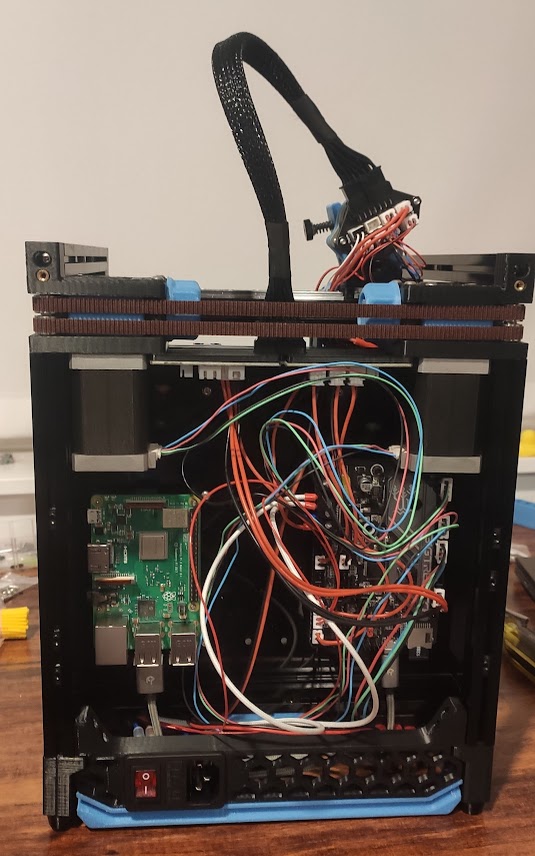

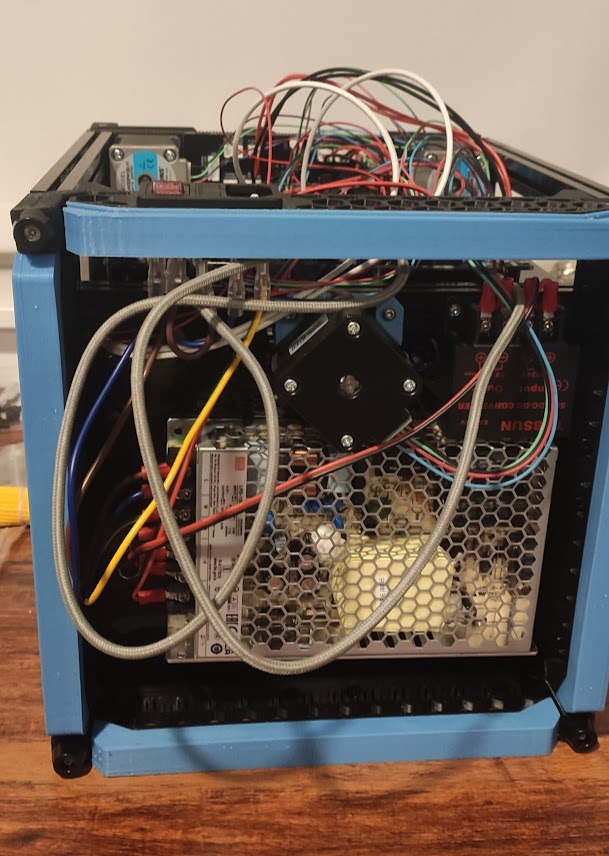

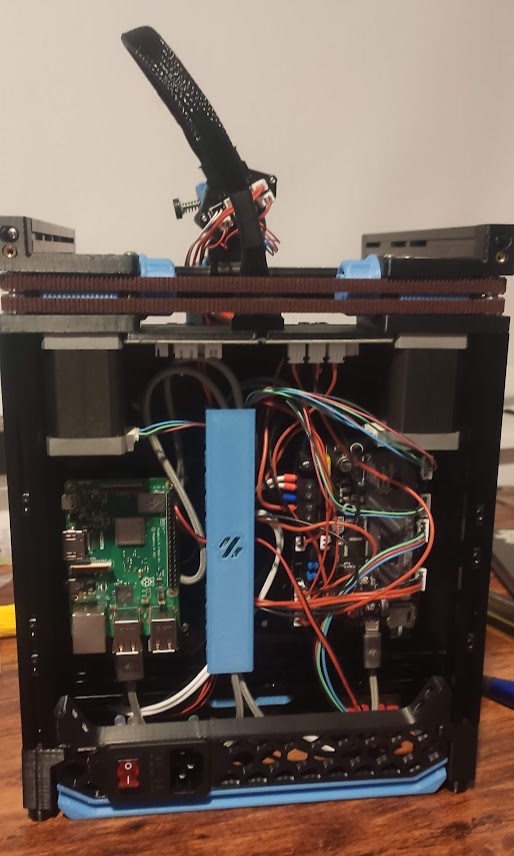

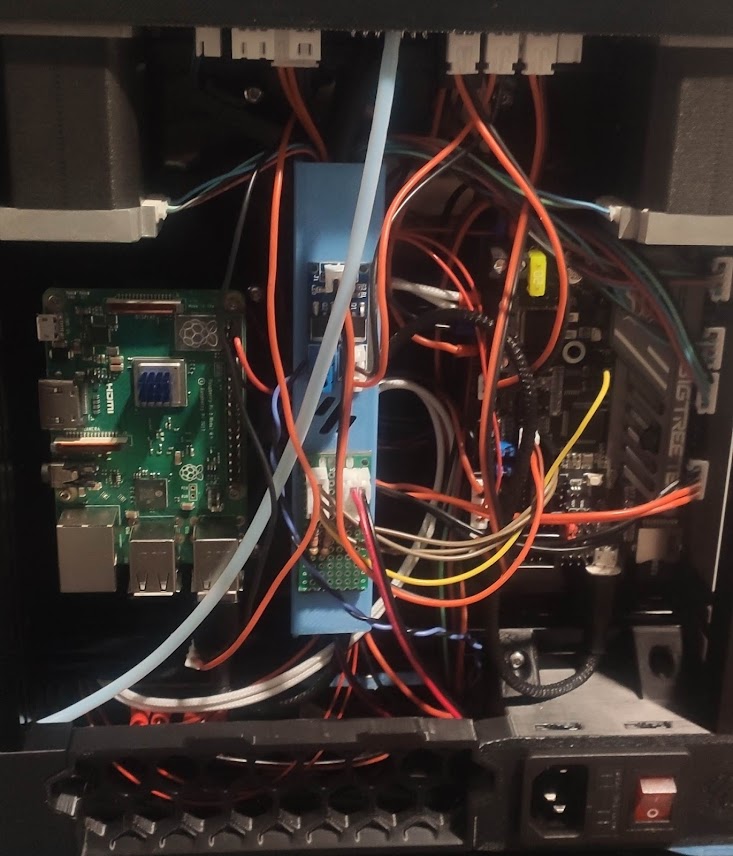

This printer is... much harder to build then a Vzbot. Everything needs to be put together in order, and if you get it wrong, you have to unbuild so much to get to the part that you need to rebuild. I can't stress how much this is tightly packed. No space in here is wasted. Packing all of the wires in there is an absolute nightmare. Even with the cable channel, it just feels like it won't fit. Managed to get it running at least, and that can be worked on.

Day 2: Onto the tuning!

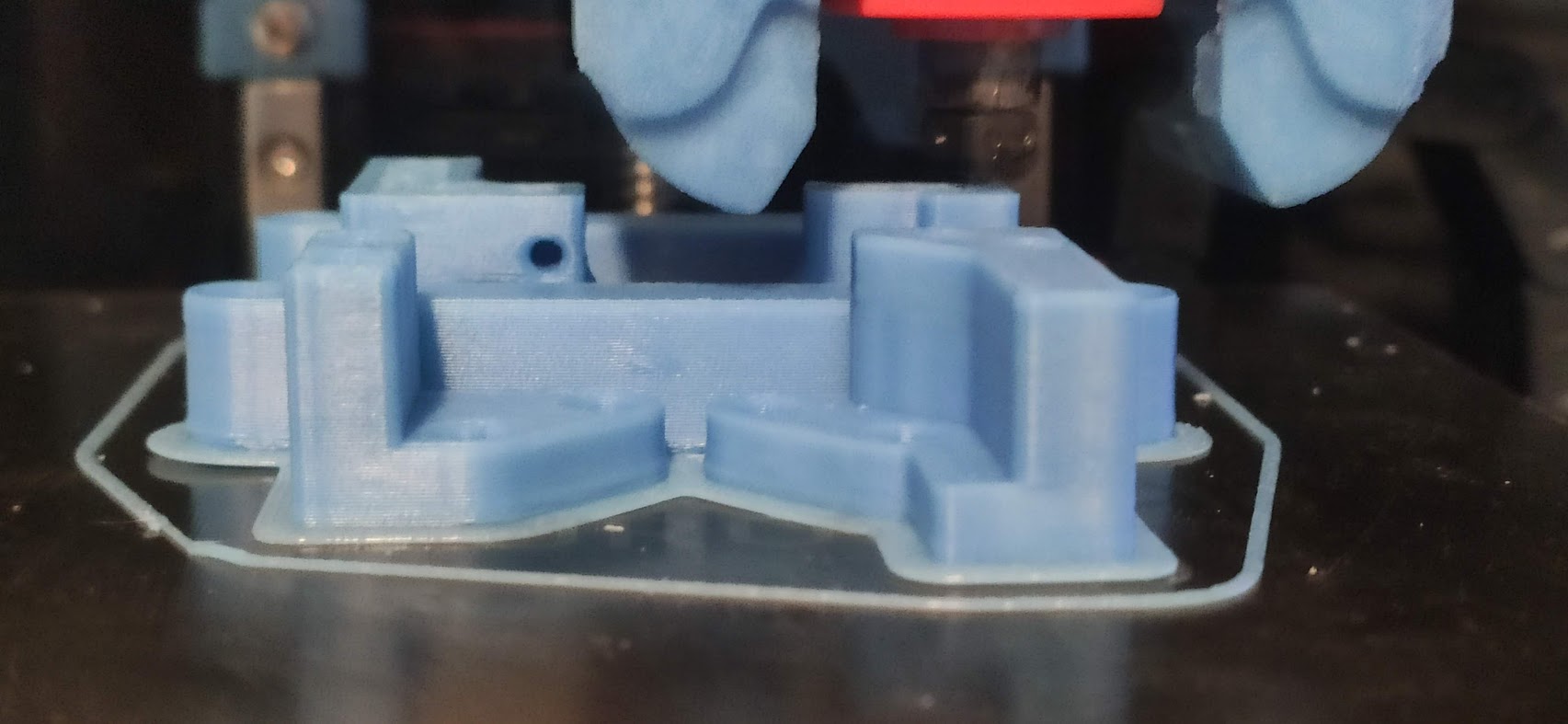

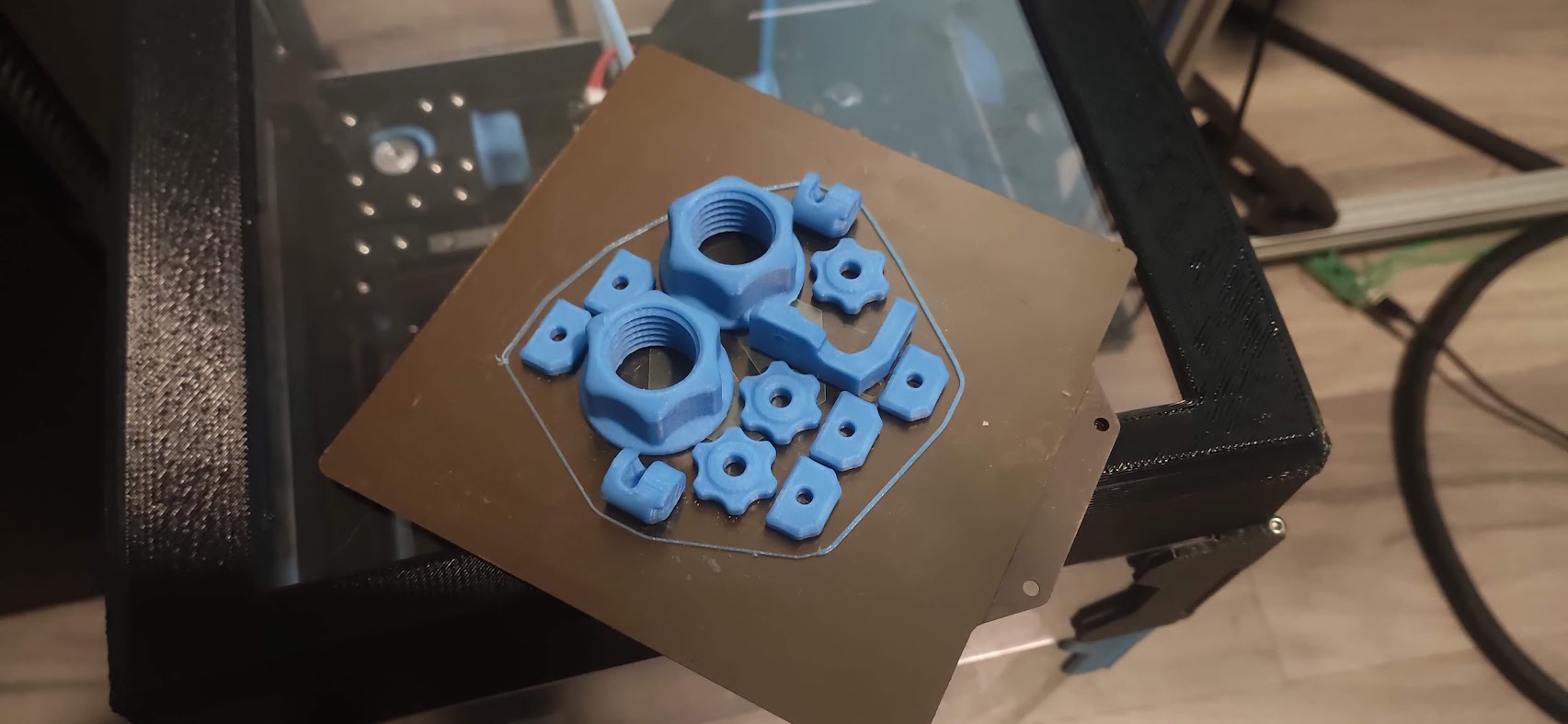

Onto day 2, and less then 24 hours after building a V0.1, the V0.2 launched. Guess it's time to tune for speed to update some things. The life of a reprap, always printing it's own updates. Gotta get some panels on this thing as well, so printing those on itself as well.

Some changes

Clean prints

Last Changes

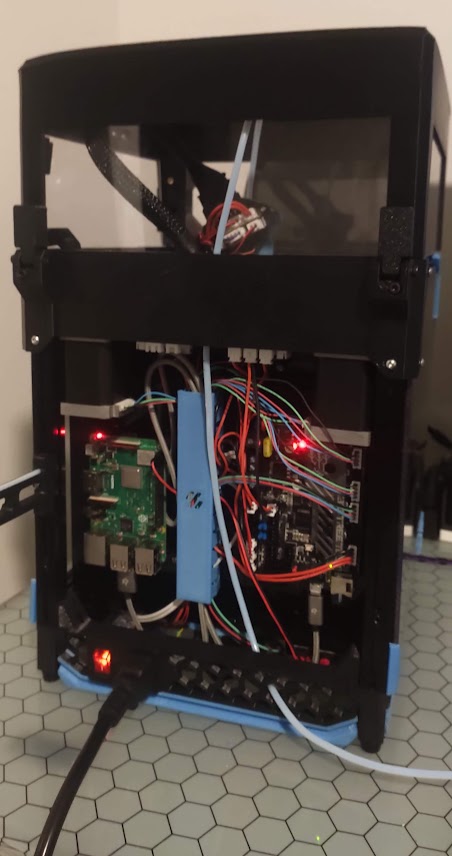

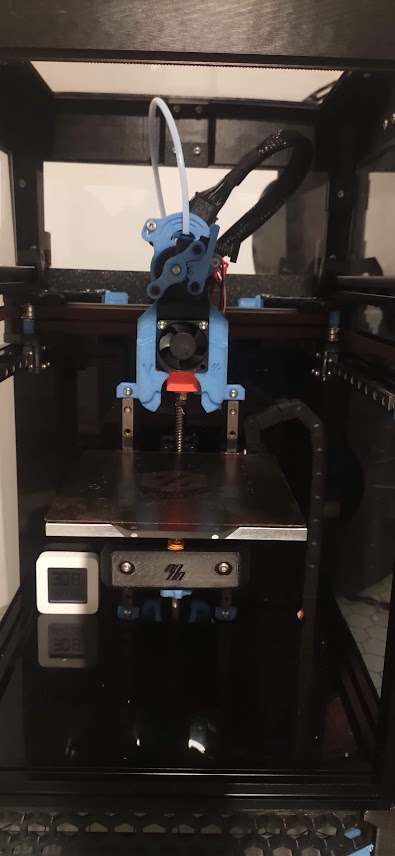

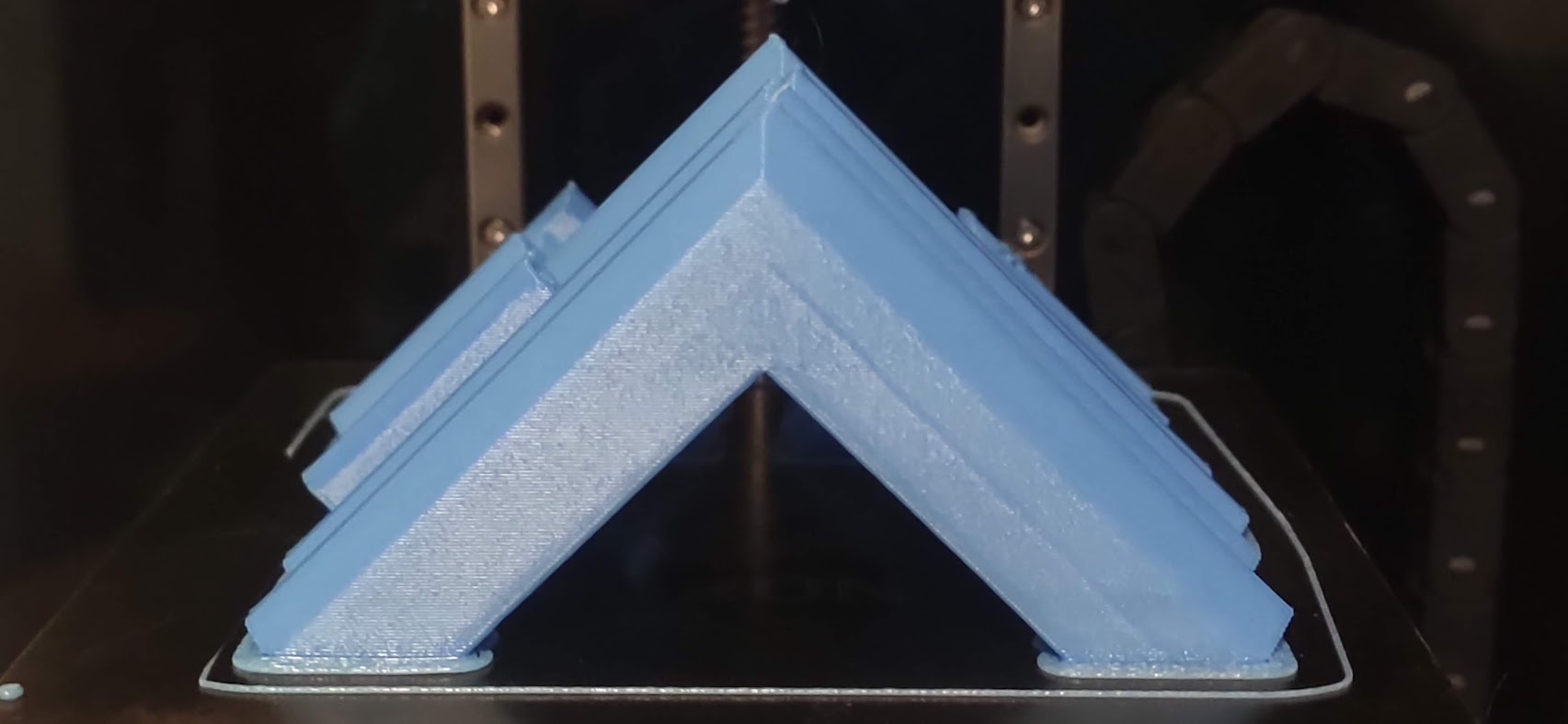

Over a bit of owning it, the V0.2 tophat parts showed up, and some shenanigans happened. I ended up popping some mosfets due to some absolutely stupid things I won't bother explaining. Cheap boards do cheap board things. I ended up also strapping on a thermistor board I built as well to get an additional temp sensor for the enclosure. It's not pretty, but it's functional. The LRS-150 power supply also had some horrid coil whine while idle, so it ended up getting chucked out and replaced with the prusa mini power supply. Same voltage/wattage, worked out. Toolhead also got replaced as cooling is an issue when you can't really delay layer switching by printing bigger, so it was replaced by a 5015 based head. Less noise, more cooling. Overall extrusion speed ended up increased despite the lower melt rate cap as you don't have to slow down to wait for cooling.

Final thoughts

This is a very niche printer. I can't print keyboard cases on it being it's only 120mm^3 build volume, but it can print a ton of my random prints that I honestly do the most often. Despite Vzbot being faster once it's fired up, it takes 10-15 minutes to warm up, and this takes less then 5 from print sent to starting printing. It's also massively cheaper to maintain with it's tiny bed and small belts and rails. While I don't think this printer is a good only printer for most people, it's an absolutely amazing printer to own as a secondary or tertiary printer. Quite limited, yet has some huge upsides. I'll either keep it basically untouched as a reliable back to back printer, or toy with new ideas on it before messing with the much more expensive Vzbot. Only time will tell.