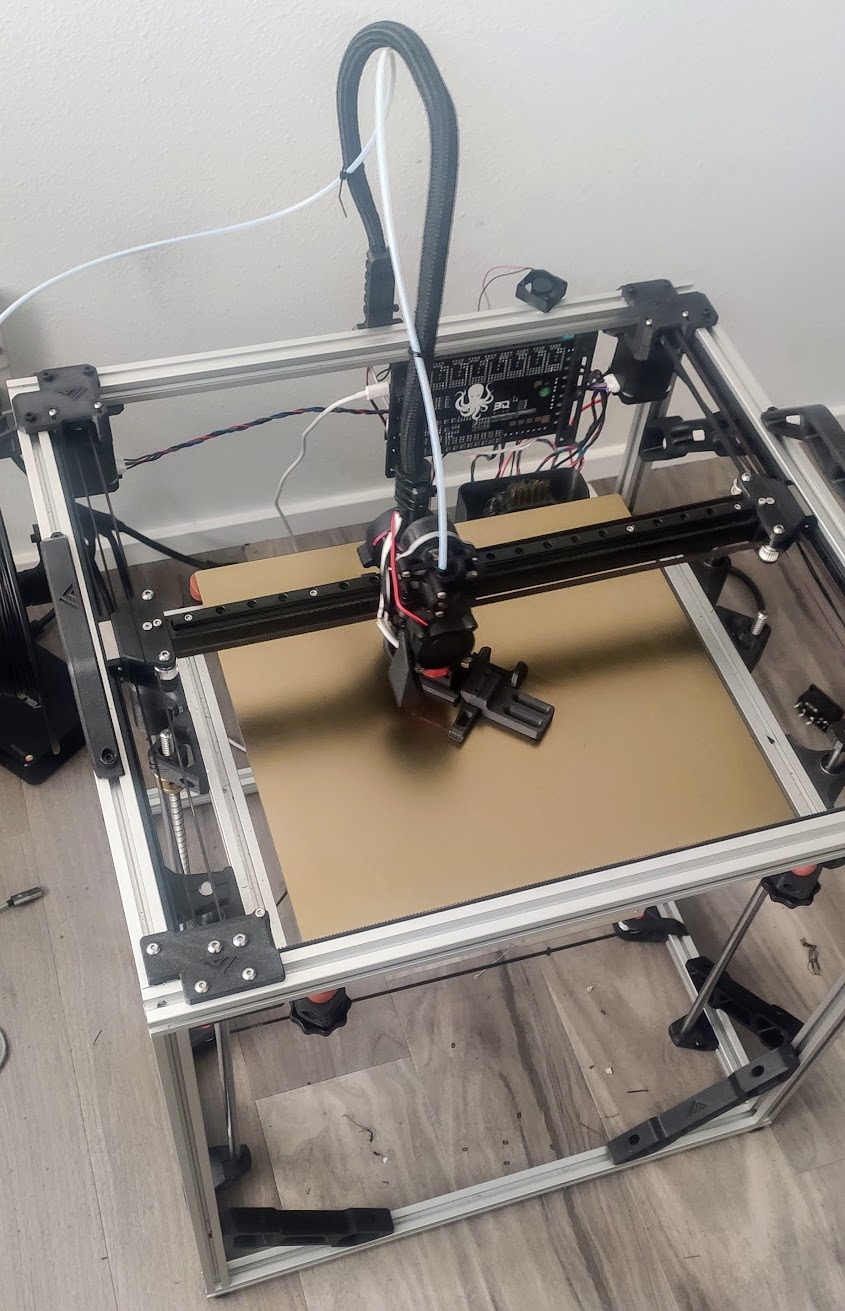

Vzbot330: The end of an era

We went really fast

Vzbot was great. It really was. Speeds and feeds were off the charts compared to my Switchwire, or even a fiend's Trident. This machine has been as much of a learning experience as Switchwire was, even though it wasn't my first printer. I built it to be as simple as possible. Less moving parts, less features, less QOL. The bare minimum. I knew that I was going to blow things up. Break them, change them, not be happy with this and that, so I went minimal to leave it as a playground, and it became one.

This time a Voron?

No. Just... Not an option. Voron design is great for a lot of things. Need lots of docs and new to custom printers? Build a Voron. Want something faster than a Prusa but don't know what to build? Voron. need a lot of hand holding and a great modding community that has decent ideas? Voron. I'm past that. Speed is not on their list of actual features, they are hostile to those interested in speed, and I'm over it. I won't say "Don't build a Voron" but unless I'm in need of a print farm asque printer that will have every QOL mod done to it and I need it cheap because kits, they aren't on my list of acceptable printers

Why a Vzbot still?

Because there's so much more room to grow with the minimal nature of the base design. I've been making upgrades, and even taking from some of the great ideas of the Voron modding community, as well as that of Annex, and other Vzbot owners. Not to mention, the speed hasn't even begun to be seen yet.

Basic specs

- Dragon High Flow hotend/Copper .4mm nozzler

- Sherpa Mini extruder

- LDO Stepper Motor - Nema 17 - 42STH48-2504AC (A/B Motors)

- TMC2209 Stepper drivers (24v)

- Octopus Pro Mainboard

- Asus Chromebox (Klipper pi replacement)

- Quickdraw probe

- F3D MIC6 Alu bed

- 120v AC heatbed

Part choice breakdown

I've added a probe to the printer even though I was mostly against it originally. I bought a very flat bed, and it prints great without a bed mesh compensation. I'm using it to automatically calculate the nozzle to probe offset so I can change out hotends/nozzles without recalibrating literally anything. This makes working on the printer much less work as I can get back to testing without a calibration again. It also lets me probe the screw points on the bed and calculate which direction and by how much to turn the screws to level the bed. Super fast bed leveling when I play with things and need to adjust it, which is rare. Wish I had that feature back when my previous hotend exploded, but whatever. It's on there now.

Other smaller changes

- Better spool holder mounted lower for less resonance

- Filament runout switch that I didn't bother to wire up

- Driver cooling fan. Almost 2A got hot

- WAY more frame braces. This thing shakes

- Cam mount for c920 webcam

- Purge bucket/nozzle scrubber. Less cleanup, low effort

What kinds of speeds can it really hit though?

Below is what I used at my daily "quality" print settings. nothing pushing the boundries, but something that would make parts that were strong, look great, and I was happy with them. There was room to push harder, but it was quite reliable.

; External perimeter

{if extrusion_role=~/ExternalPerimeter/};[extrusion_role]

SET_VELOCITY_LIMIT ACCEL=8000 ACCEL_TO_DECEL=8000 SQUARE_CORNER_VELOCITY=8

; Perimeter

{elsif extrusion_role=~/Perimeter/};[extrusion_role]

SET_VELOCITY_LIMIT ACCEL=15000 ACCEL_TO_DECEL=15000 SQUARE_CORNER_VELOCITY=15

; Overhang perimeter

{elsif extrusion_role=~/OverhangPerimeter/};[extrusion_role]

SET_VELOCITY_LIMIT ACCEL=10000 ACCEL_TO_DECEL=10000 SQUARE_CORNER_VELOCITY=15

; Internal infill

{elsif extrusion_role=~/InternalInfill/};[extrusion_role]

SET_VELOCITY_LIMIT ACCEL=40000 ACCEL_TO_DECEL=40000 SQUARE_CORNER_VELOCITY=20

; Top solid infill

{elsif extrusion_role=~/TopSolidInfill/};[extrusion_role]

SET_VELOCITY_LIMIT ACCEL=10000 ACCEL_TO_DECEL=10000 SQUARE_CORNER_VELOCITY=8

; Solid infill

{elsif extrusion_role=~/SolidInfill/};[extrusion_role]

SET_VELOCITY_LIMIT ACCEL=20000 ACCEL_TO_DECEL=20000 SQUARE_CORNER_VELOCITY=20

; Bridge infill

{elsif extrusion_role=~/BridgeInfill/};[extrusion_role]

SET_VELOCITY_LIMIT ACCEL=10000 ACCEL_TO_DECEL=10000 SQUARE_CORNER_VELOCITY=15

; Gap fill

{elsif extrusion_role=~/GapFill/};[extrusion_role]

SET_VELOCITY_LIMIT ACCEL=10000 ACCEL_TO_DECEL=10000 SQUARE_CORNER_VELOCITY=15

; Skirt

{elsif extrusion_role=~/Skirt/};[extrusion_role]

SET_VELOCITY_LIMIT ACCEL=10000 ACCEL_TO_DECEL=10000 SQUARE_CORNER_VELOCITY=15

; Support material

{elsif extrusion_role=~/SupportMaterial/};[extrusion_role]

SET_VELOCITY_LIMIT ACCEL=10000 ACCEL_TO_DECEL=10000 SQUARE_CORNER_VELOCITY=20

; Support material interface

{elsif extrusion_role=~/SupportMaterialInterface/};[extrusion_role]

SET_VELOCITY_LIMIT ACCEL=10000 ACCEL_TO_DECEL=10000 SQUARE_CORNER_VELOCITY=20

; Thin walls

{elsif extrusion_role=~/ThinWall/};[extrusion_role]

SET_VELOCITY_LIMIT ACCEL=10000 ACCEL_TO_DECEL=10000 SQUARE_CORNER_VELOCITY=8

; Other

{else};[extrusion_role]

SET_VELOCITY_LIMIT ACCEL=10000 ACCEL_TO_DECEL=10000 SQUARE_CORNER_VELOCITY=15

{endif}

What's next?

Already in my hands are 2 more motors that will be replacing the front idlers. This both increases torque and decreases resonance. This will both allow for more "yolo" accels just to show off, but it will also increase usable accels. This means getting especially small parts done even faster. I'm replacing the .4mm copper nozzle with a .5mm tungsten carbide nozzle. Not only can it handle abrasives, it will outlast the printer, and it's a high flow nozzle. More melt speed, faster prints. Back pressure of a .4mm nozzle alone was causing flow issues, and greater line widths allow for an imperceptible loss of detail. Also coming is the Mellow meltzone extender. This should add a bit more melt power and really help me get the flow up. I'm massively limited especially on infill with 26mm^3/s of flow (101m/s on x/y motion), so getting the flow up will drag print times way down where flow limits were hit. A short list follows.

- .5mm TC nozzle

- Meltzone extender

- 2 more motors. QuadXY/AWD incoming

Eventually

On my far list, probably this winter is replacing the frame to fully support a rigid enclosure with a big door. Switching up a few parts with a custom Trident like design, but adding in some Y braces made of 2040 extrusions to cut down on the frame sway due to inability to bolt the printer to the wall. Yes, that's normally the solution at these accels.

Some pictures/videos

Daily print speeds. Testing accuracy. It was dead on, and moved perfectly.

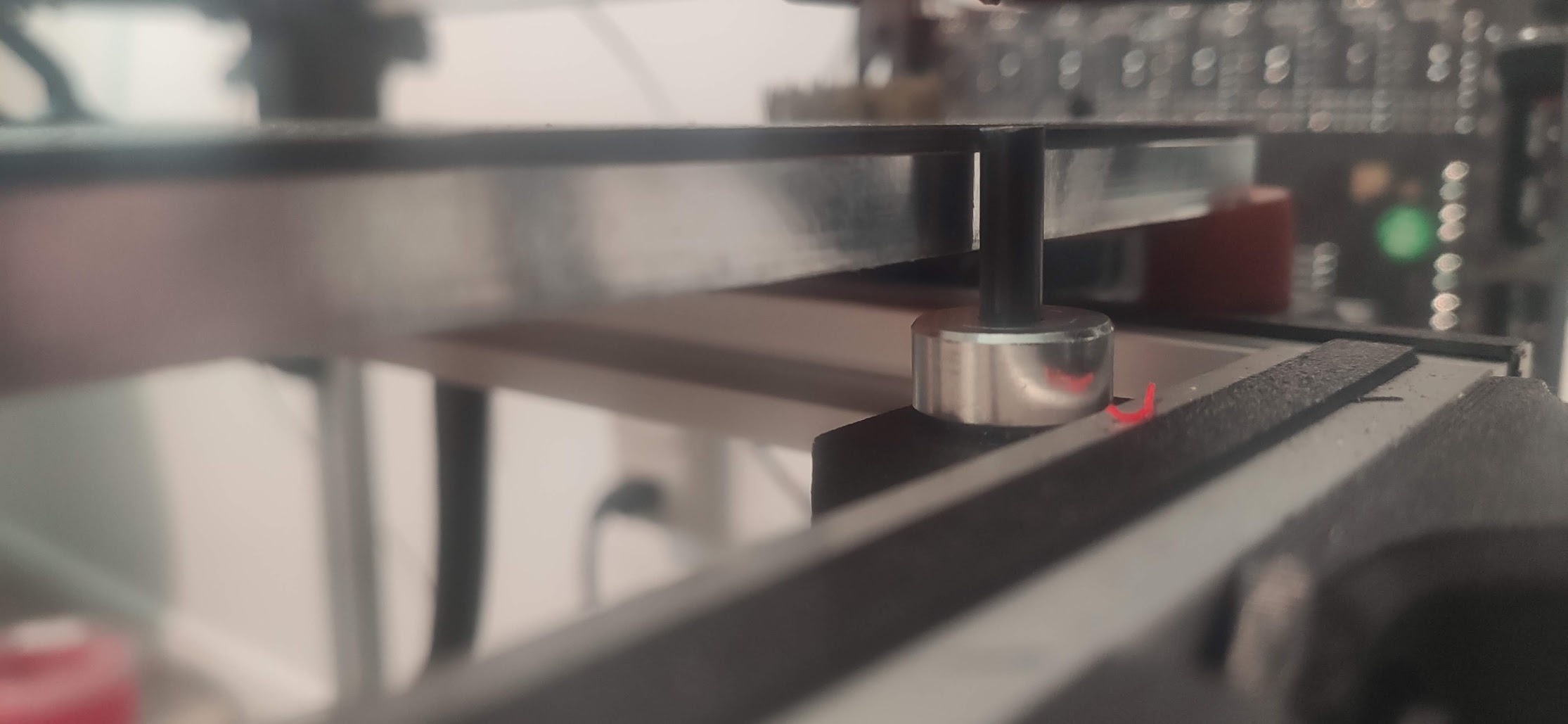

Klicky got replaced with quickdraw, but I tried it.

Nozzle endstop for auto calibration

And... The obligatory speed benchy at 45k accels. Because why the heck not.