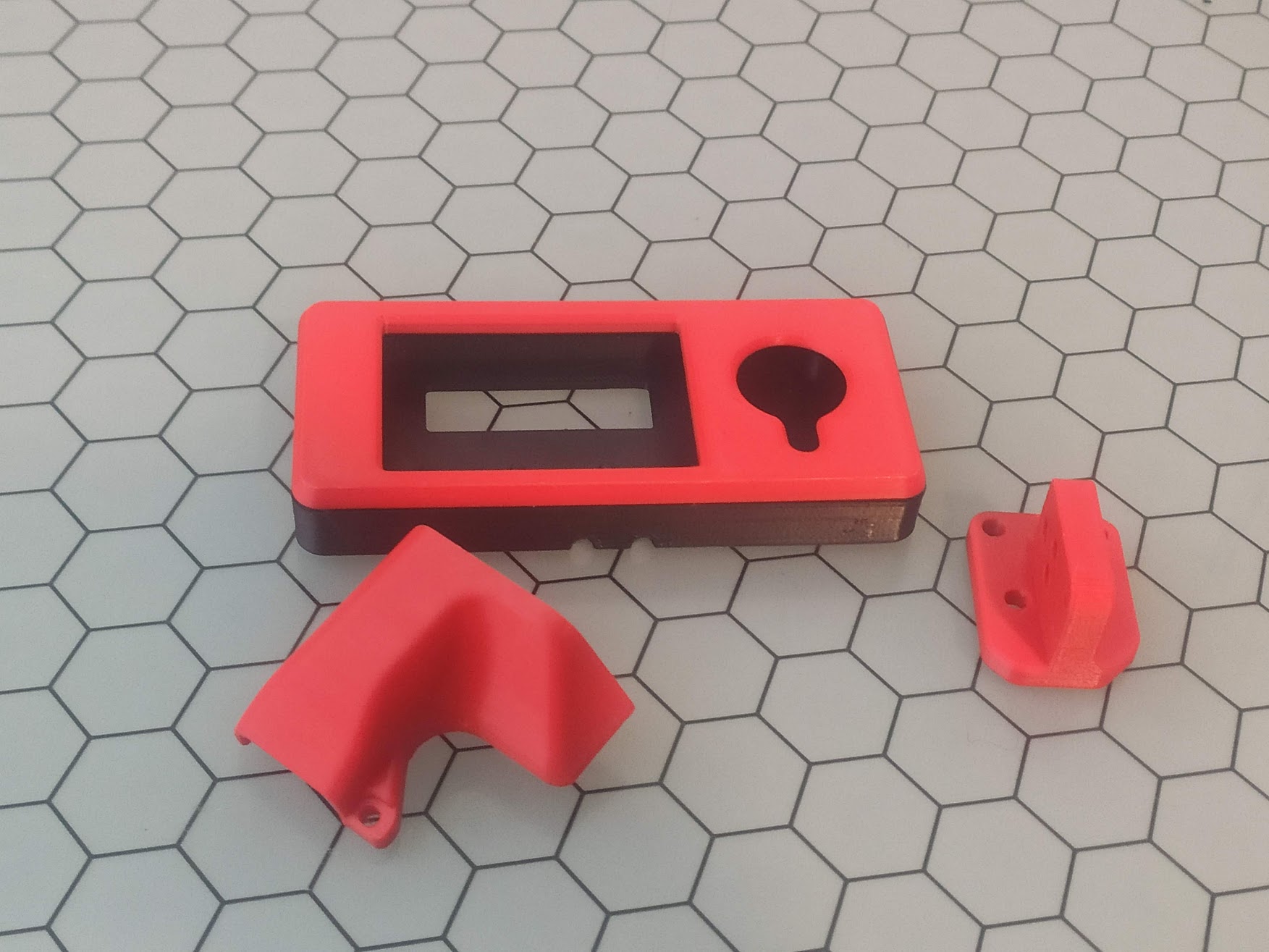

PolyLite: ASA Red and Black

Hard to print, but rewarding

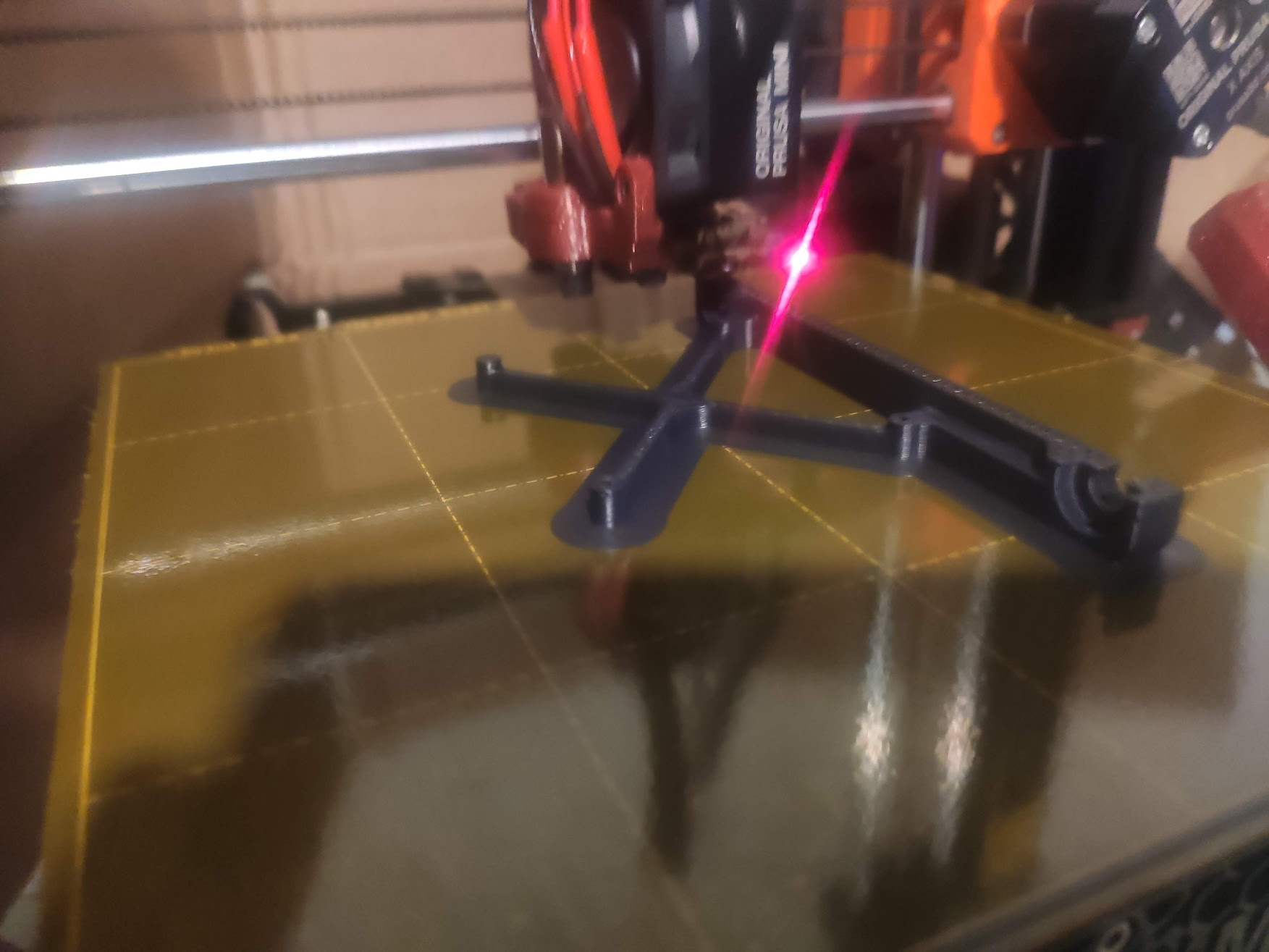

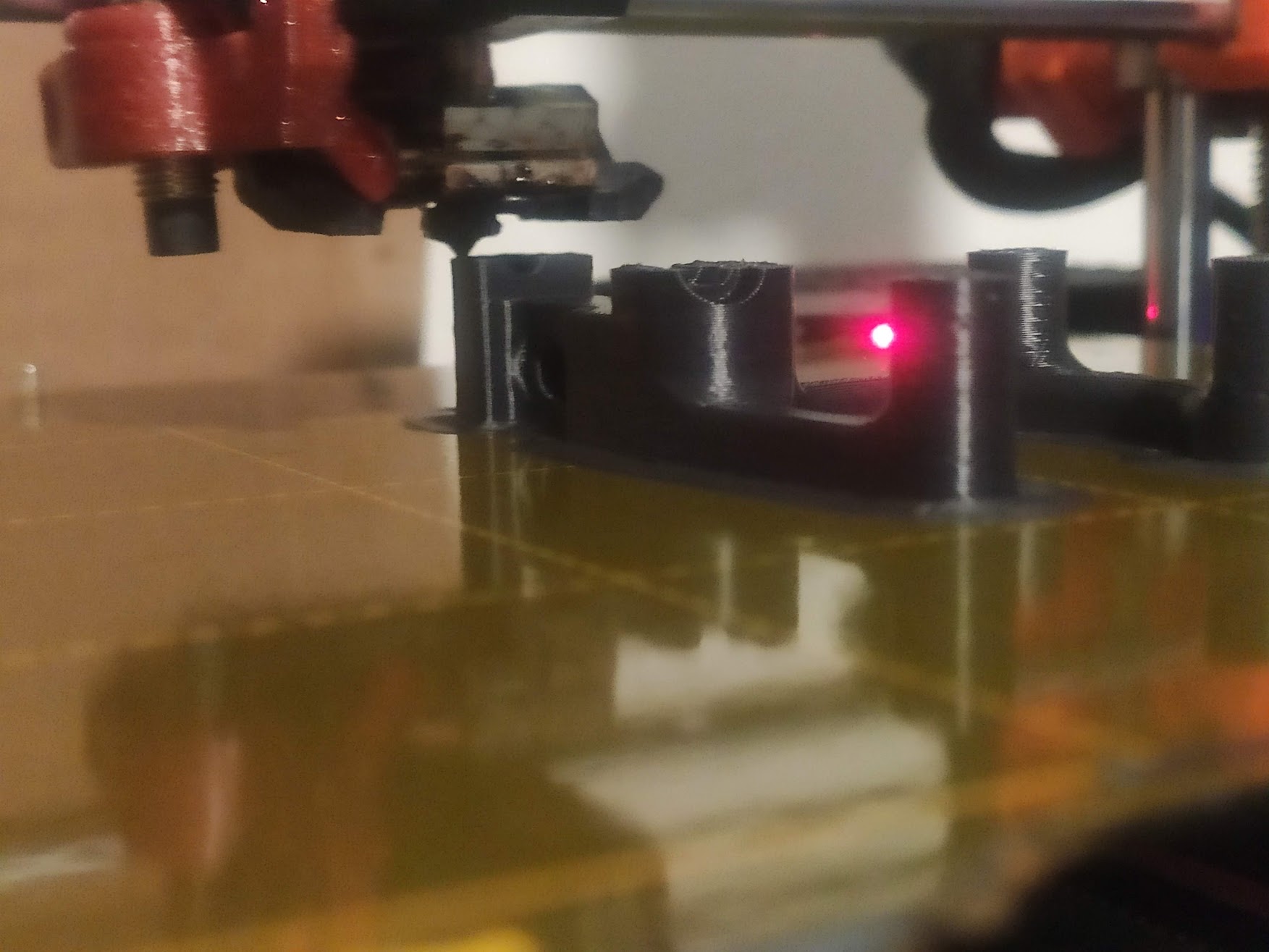

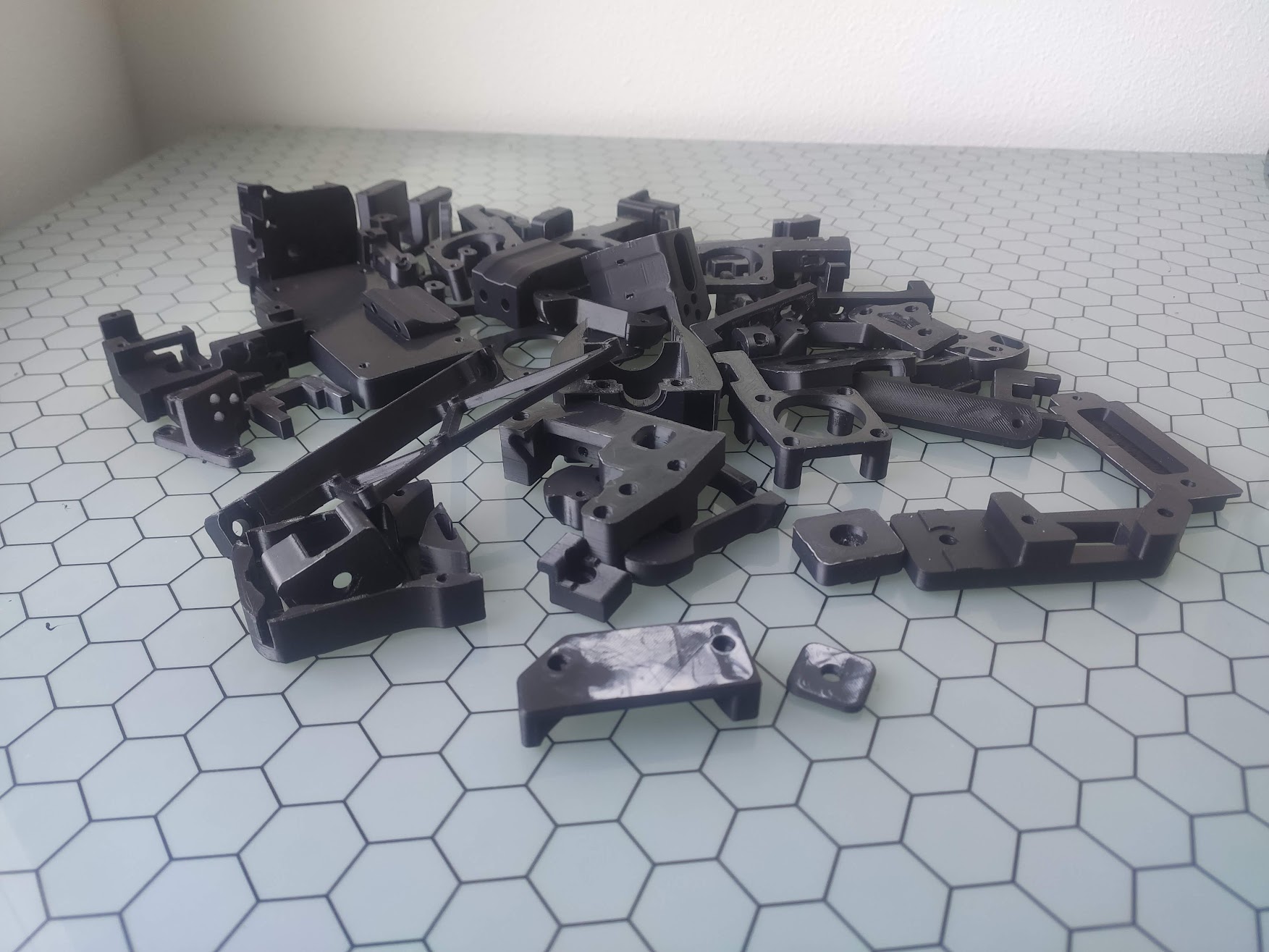

ASA is not at all like PLA. It's much stronger, resists temperature higher than 50c, and unlike ABS, it's even UV resistant. I wanted to start printing things that were able to be much stronger, and even mechanical. Gears, motor mounts, things near a printer's hotend, and much more will do much better out of ASA than they would out of something like PLA. ASA is much like ABS in regards to how it's harder to print. It has a tendency to warp when the surrounding air is under 50c because of the large difference between the printing temperature and the cooled temperature. Bed adhesion is also something to consider to help prevent warping. This is where I learned my first lesson with ASA. It really loves to stick to PEI sheets like the Prusa Mini has.

Damaged PEI sheet

While some small prints seemed to do great, I soon found that they stuck too well. Well enough that I had to pry the print off. Be very careful when printing with ASA to make sure that it's squished with your Z offset, but not enough to turn it white. I later learned that when it goes white, it's under stress, which causes a bond too strong, and leads to damaged PEI sheets. C'est la vie. I picked up some large kapton sheets, and swapped out the PEI sheets on both sides with that, and have been printing ever since. It doesn't stick nearly as hard to anything, which is both a plus, and a minus. It's a tradeoff I'd like to have as long as I have both PEI and Kapton available. If you ever damage a sheet too badly, order a new one, but save the old one for Kapton or painter's tape. Never know when it'll come in handy.

Back to printing!

With the sheet switched out, I learned a few things, and some were quite conflicting. The glass transition temperature of PolyLite ASA is apparently 97.5c, so you would want to run your bed temperature under that, as stated on the spool. However, my prusa mini lacks an enclosure, and should stay that way being built out of PETG, so putting the bed temperature at 100c and using a brim allowed me to get quite a strong grip on prints while printing, but it released instantly after cooling down without fail. If you are on PEI, I'd recomment trying without a brim, and keeping temperatures down, as well as bringing up your Z offset a bit to ensure that prints don't stick too well, but with Kapton tape, the settings I've listed seem to work great. When in doubt, print small objects, or calibration tests to test before you make the mistake I did.

Conclusion

This is not the "don't think, and just press print" that PLA has gotten me used to, but it's wonderfully strong, doesn't smell bad like ABS, and prints pretty reliably after getting it set up for your specific printer. I don't think I'd make ASA my default, but when something needs to be strong, ASA is my new go-to.