Prusa Mini: Initial thoughs

How good can it be for $400?

Short answer: Amazing. Buy one right now, then come back to read what you just got for your money.

The longer answer is probably why you are here, so I guess I should stop stalling. I've played with other's printers on and off for years. I hear other people that have 3D printers complaining that it's basically just another project car. Something you sink money and time into, and it gives you nothing but problems, but you enjoy it for the hobby. This is exactly what I didn't get with the Prusa Mini.

So how many issues did I have?

First off, I decided that a kit was not for me on my first printer, so I got it assembled. Right out of the box, I opened the printer and put in a few screws, and plugged in a few wires. Because I had no clue what I was doing, it took about an hour or two, but it over all was pretty easy. Loaded up some Galaxy Black PLA that came with the printer that was packed in for testing, set the Z offset with on screen instructions, plugged in the included USB drive to the printer, found something that looked interesting, and hit print. With zero effort, and no mistakes, the first print came out looking stunning, and everything I've printed since then in the same Galaxy Black has come out looking just as good.

But I have to complain about something

PETG IS ABSOLUTELY A NIGHTMARE TO WORK WITH! I printed about half of my spool of Galaxy Black PLA, and loaded up some PETG, switched out the bed for the textured sheet as was instructed, switched out the spool, and set the Z height for the new bed. Off to the races right? No... Conveniently, Prusa has profiles for their filament in Prusa Slicer, so everything you could need to tune for the printer, or the filament is basically done for you. It's even labled on every spool, what the temp range for the nozzle and bed should be. Easy enough right? Print after print, PETG failed. Lifting from the bed, sometimes even on the first layer. I contacted support, who was absolutely fantastic, generating things for me to print to test, offering me advice on things that could be physically wrong, and more. They stayed on the chat with me for several hours before I gave up for the day, and went to sleep. I ultimately discovered that the edges of my bed were lower than expected due to a draft from the nearby window cooling the plate down faster than it could auto react. I bumped up the heatbed issues, and haven't had sticking issues since. I'll ramble more about materials later in a separate post though, but know that some materials are amazing, and some need a bit of work.

This sounds mostly bad so far. Why do I want this?

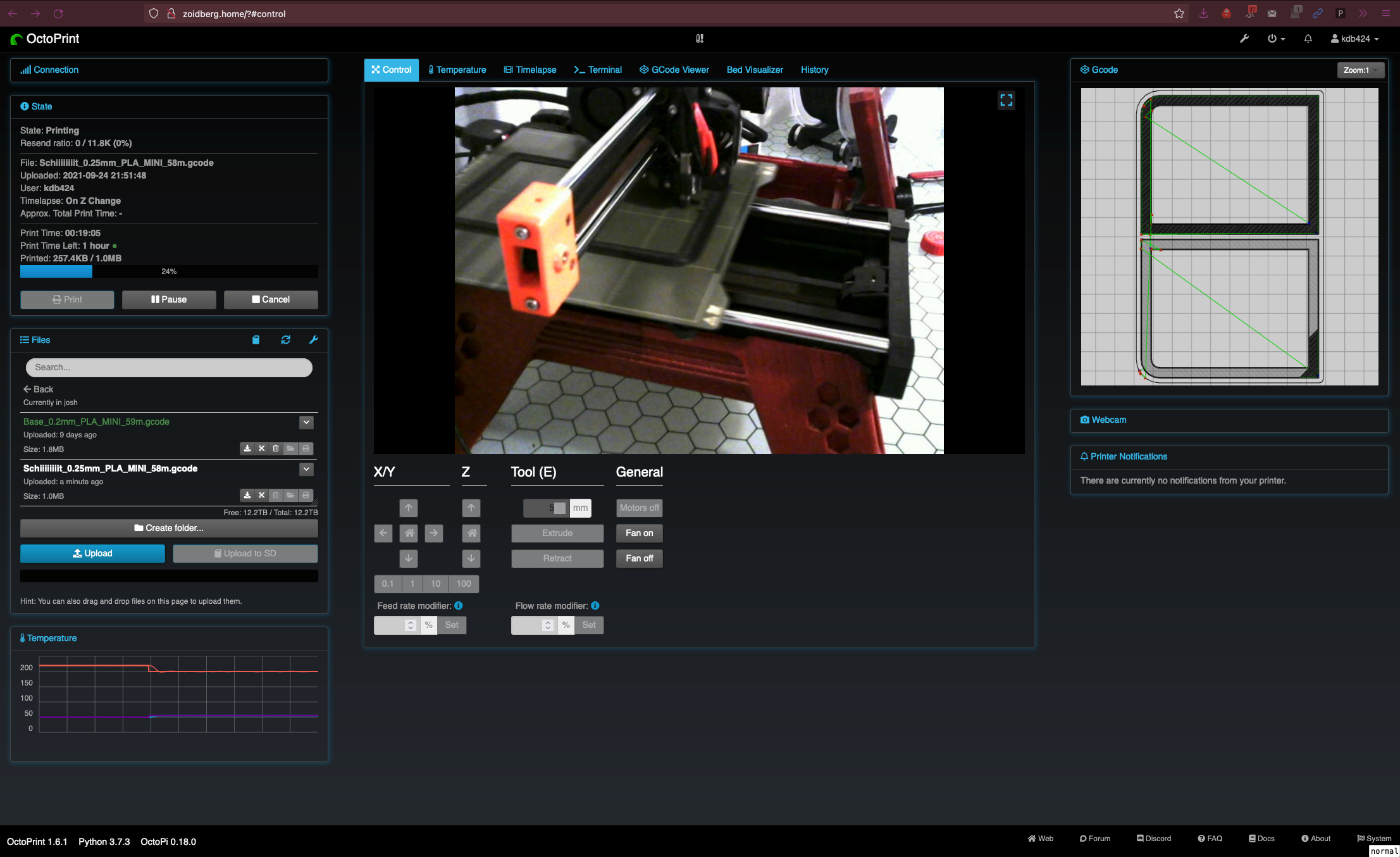

While I did complain a bit about PETG, that ended up mostly user error as most people don't keep a printer by the window in the pacific north west where the nights cool rapidly, so this won't be an issue. I could have also asked around, and learned that a simple and cheap pop up enclosure would have fixed many of my issues as well. For only $400 USD, I got a printer that will print Prusa PLA right out of the box, even in subpar temperature conditions to the point that I was convinced that it should all be that easy, because it required no thought. I could start printing a keyboard case, and leave for work after I saw one layer go down, I could trust that when I got home, I would have a keyboard case, and did.

Conclusion

These are just my initial thoughts on this printer, and I'll be doing more on 3D printing. I think I'll have a lot of topics to talk about that others will be interested in. This is a great printer out of the box, but there's a world more that can be done, and not even risk the near perfection that you get out of the box. For now, I'll just leave this as a teaser.