Prusa Mini: Long term review

TLDR: Buy a prusa printer right now.

With that out of the way, let me say that this printer has been the best introduction into 3D printing that I could have asked for. The only experience that I had previously was at least 6 years ago, and it wasn't my printer, but one I was allowed to play with. That was a tinker toy back then, even retailing at over $1000 USD. Constantly having issues with prints not sticking, bubbling plastics, prints getting stuck to the nozzle, the list goes on. The prusa mini has been an absolute dream compared to what I was used to before. I'll do some mini reviews of different parts, and specific things like the exact filament brands, I'll do a full review of later, so look forward to that.

Printing quality

rinting quality on this has been absolutely fantastic. I've been printing almost non stop on it since I've had it with the exception to over night. More on that below. I've printed a stand for my mac mini, a stand for my mouse, under desk cable hooks, countless calibration cubes, low poly pokemon decorations for my desk, keyboard stands, a corne LP case, I can go on and on. Things look absolutely amazing coming off the printer with little to no cleanup needed depending on the model. If I want something fast, 0.25mm in the slicer looks "good enough" and for keyboard cases, or other desk things, 0.15 looks amazing. Bringing it all the way down to 0.07 though, and the detail gets unreal at the cost of this printer.

Printing speed

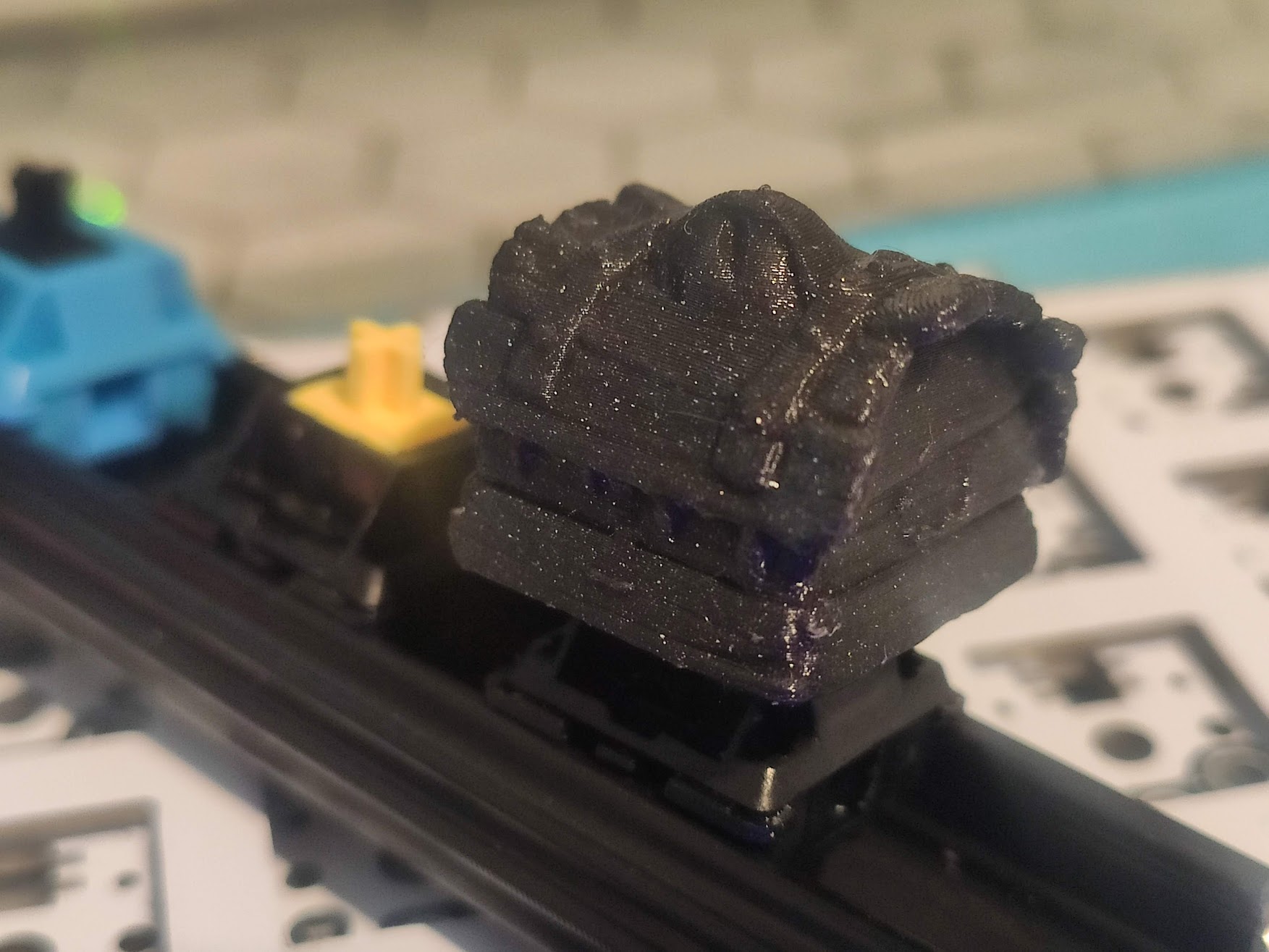

If you set your expectations reasonably, this printer is more than fast enough. My corne LP case was printed in ~5.5 hours per half, at stock prusa settings with their Galaxy Black PLA, and it looks incredible. That's not long at all to wait for something that looks like this. I have gotten a need for speed due to the sort of person that I am. I can't ever just leave anything at stock settings and be happy, but if I didn't have the option to change them, I would still say that I absolutely would still own one of these printers. I'll make a follow up post explaining how I am tuning the printer for speed though for those interested. For now, have a pretty corne picture.

Noise

This is by no means a loud printer. Many would be fine sleeping right next to it, and not being bothered. I, unfortunately am not that type, but I do run it on a table right next to my main desk while I do other tasks all day, and even have open back headphones and it doesn't bother me at all. If you start raising the speeds as I have, you'll probably want to get some anti-vibration feet for your printer/desk as it can get loud, but if used "as intended" it's more than acceptable to work next to unless you are one who demands absolute quiet. Chuck it in a closet and close the door, and you'll never know it's there though.

Software UI

Out of the gate, I used PrusaSlicer mixed with the on screen display to select my prints that I saved to the included USB drive. It worked about as well as anyone could ever expect.

- Built in wizard to help you get set up and running

- Change filament list with predefined options

- Auto bed leveling

- Easy Z offset adjust for when changing beds out

- Ability to speed up/slow down prints live, or even change filament on the fly

The slicer was also super easy to get started with, and tuned directly for Prusa printers, not that it won't work with other slicers, or the slicer with other brands, but it was a fantastic experience sticking in the ecosystem. Very few issues, and when I finally had an issue, customer support was great, and helped me out for hours to the best of their ability.

Textured bed

Speaking of customer support, this is how I got there. Different plastics need different beds. I got both PLA, and PETG with my printer to start, and PETG does not get along with the flat plate. Actually, it won't ever let go of it, but you get the point. The textured bed was recommended for PETG, so I figured, sure, let's do this. I could not get anything to stick to this bed. After much wasted plastic, and frustration, I contacted support. They took me through bed leveling, sending pictures to have them suggest what could be wrong, sending me test files to print, and offering tips like to clean the bed with isopropyl alcohol of at least 90%. In the end, I let chat go cold, and gave up for a while. I must state right here, do not buy this textured sheet. Many many users report issues with it, and many of the clones work much better, and cost less. I hate supporting knockoffs, but when they are actually good, and the "real thing" isn't, I can't help but steer you to them. They can be found all over Aliexpress, or ebay, and those links never last, so give them a search. When you come back, I'll explain how I can sometimes get a print on this horrible sheet that I wish I didn't buy.

-

Wash with soap and a soft scrub brush. Not metal, plastic only

-

Bypass the built in Z offset for this sheet, and go directly to the paper test

-

Prints will stick most of the time, but still not enough that I'd ever even think of walking away.

The textured sheet is not needed for things like PLA, so if you can avoid the need of PETG or other materials that require the sheet, then you can just omit this entire rant as the flat stock sheet is incredible. I'll go more into PETG in a review of the filament in it's own article.

Conclusion

I absolutely would recommend this to anyone that has had a bad experience with 3D printing, wants a printer that they can trust will work every time, wants to get into 3D printing and doesn't know where to start, or even for teaching kids (with supervision) about CAD, engineering, ect. I'm more than addicted to 3D printing now. From the parts that I can print for my printer to upgrade itself, or drawers for my keyboard stuff, or anything I could imagine (that will fit on the build plate), is just a print away, and I haven't even learned any CAD to build my own things. I'm sure I'll have a lot more to say about this in the future, so I hope you like 3D printing as well.