Time to go really fast

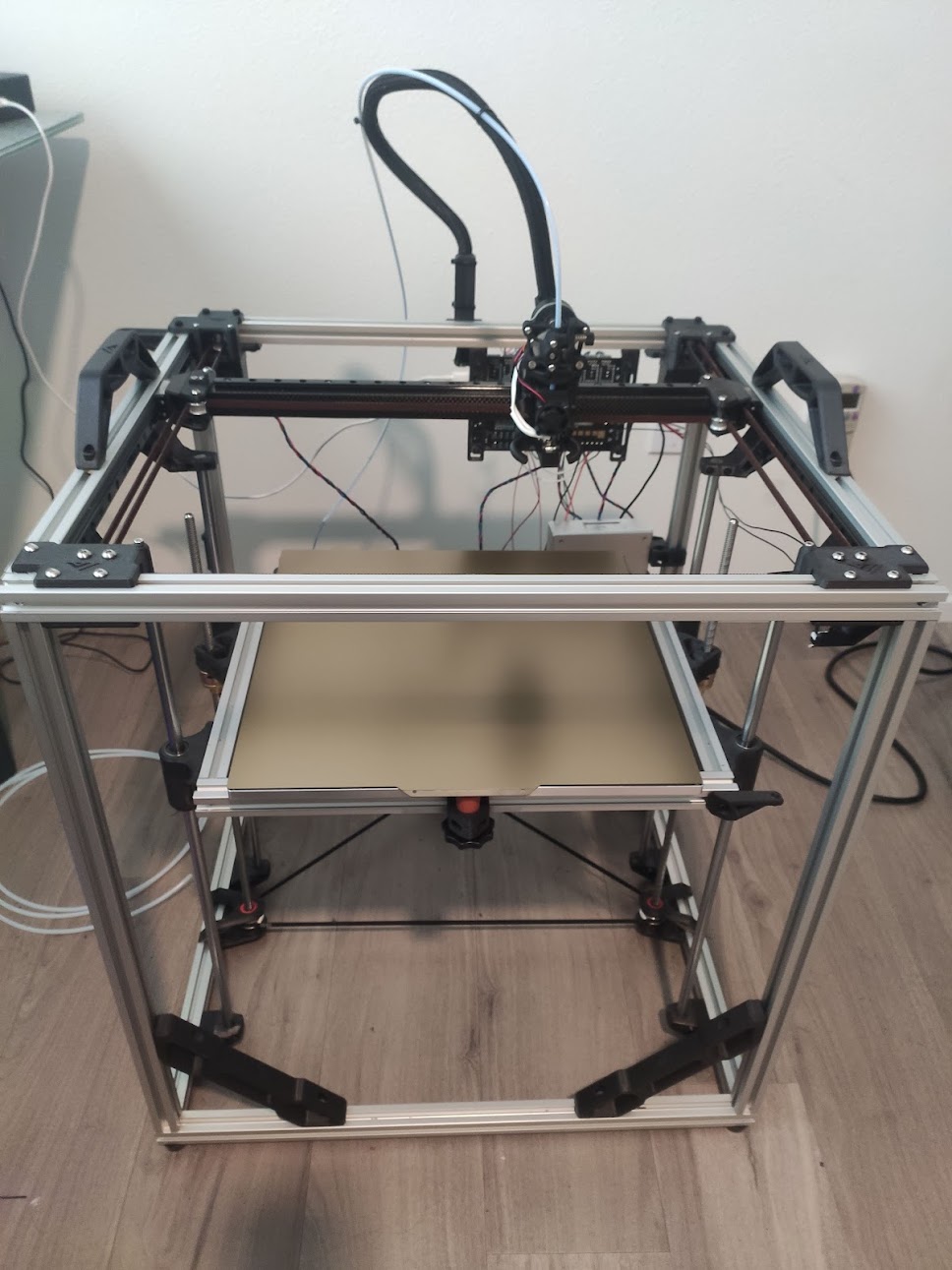

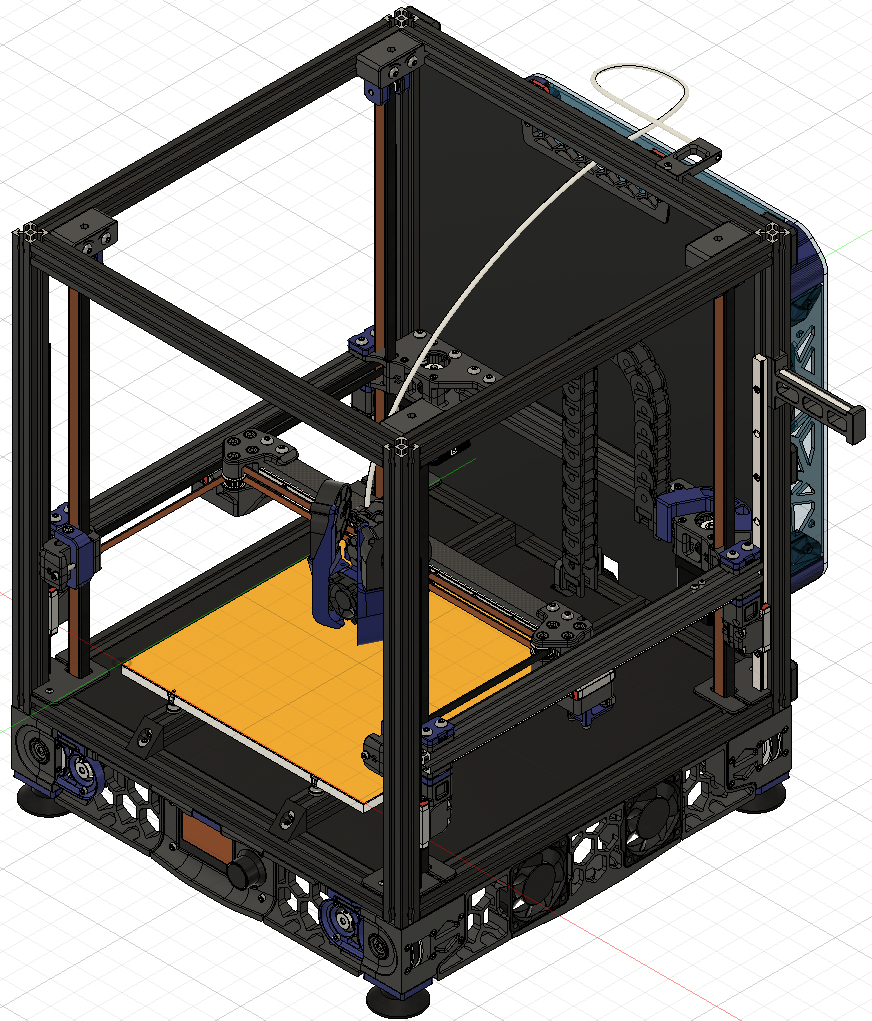

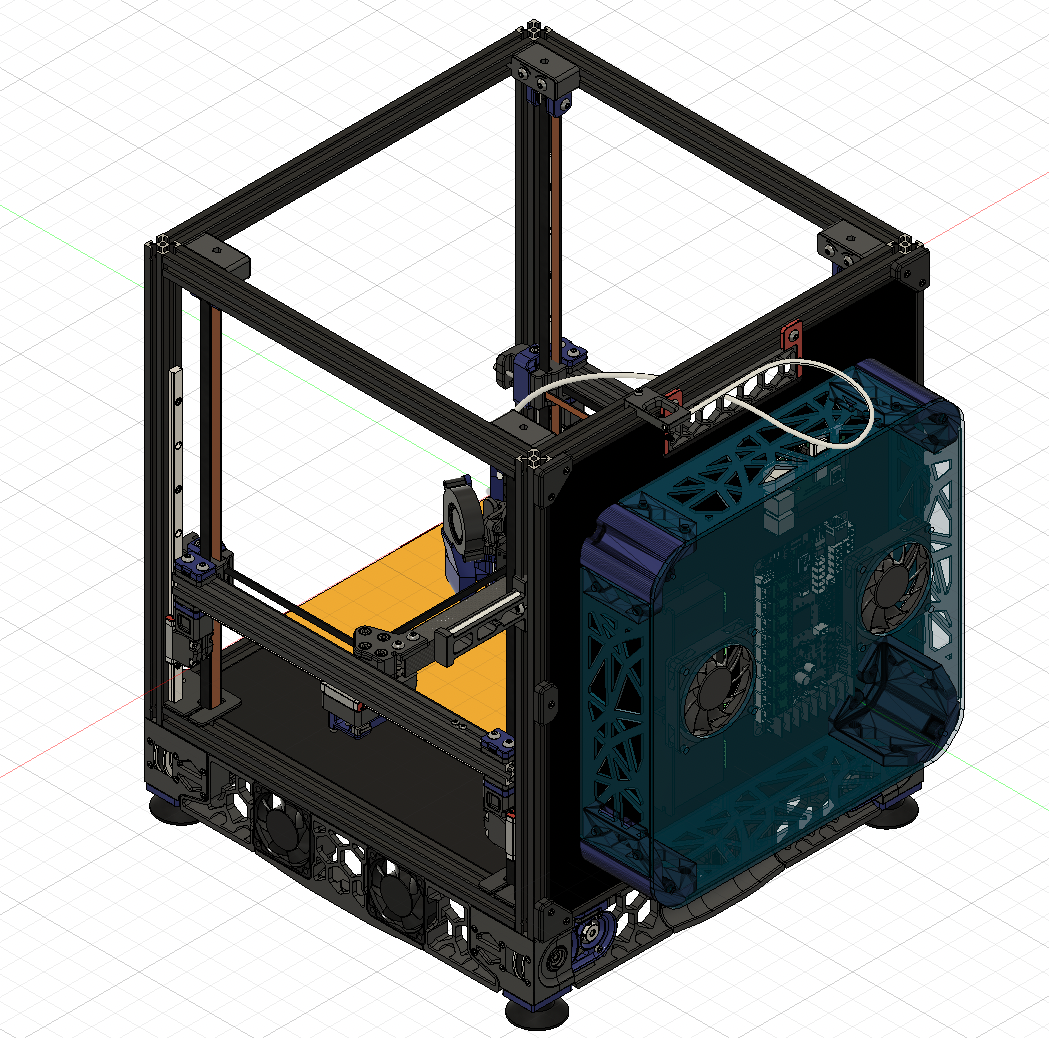

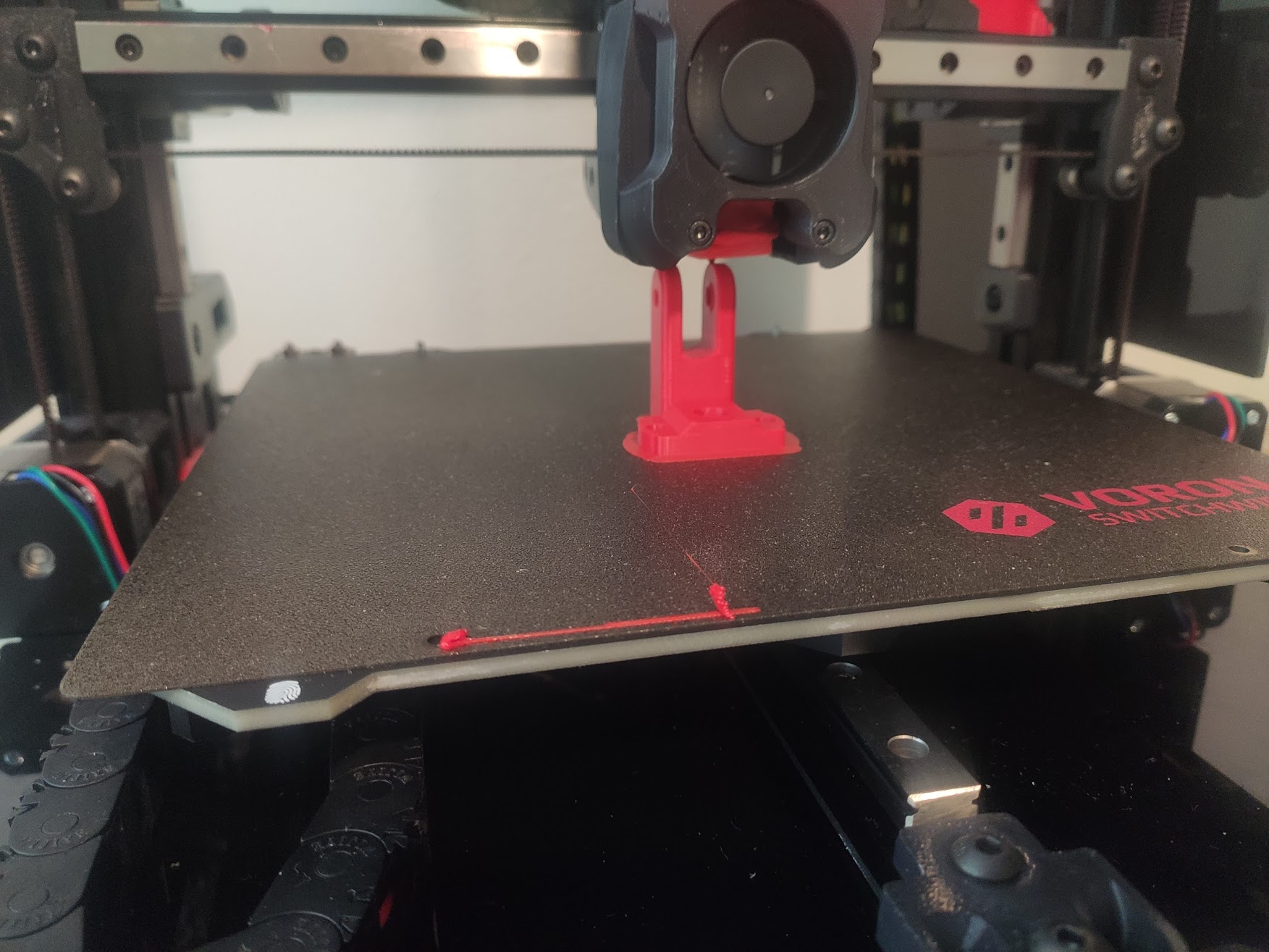

I spent quite a bit of time designing modifications for Vorons, and couldn't really agree with their limits and bad design choices. That lead me to looking for a better base printer design. I stumbled onto Annex and Vzbot series printers, and for cost reasons alone, I decided that a Vzbot 330 scratch build was what I was insane enough to build.

Why not a Voron?

I've got a few reasons that I am not interested in most Vorons. I won't get into personal disagreements with certain people, but just in design. Voron is not meant for speed. The designs are very well built for the speeds that they target, being "faster than most consumer printers", but they are not really built with the intentions of going much faster. The toolhead for example hangs on the front of the rail, and the rail on the front of the extrusion. That leaves a huge cantilever when doing fast Y movements on a CoreXY system, leading to inaccuracy, larger vibrations leading to ringing, more wear on components like the rails, ect. They pride themselves in looking really cool, and being easy to build for newcomers thanks to great documentation, and they nail that.

Why a Vzbot?

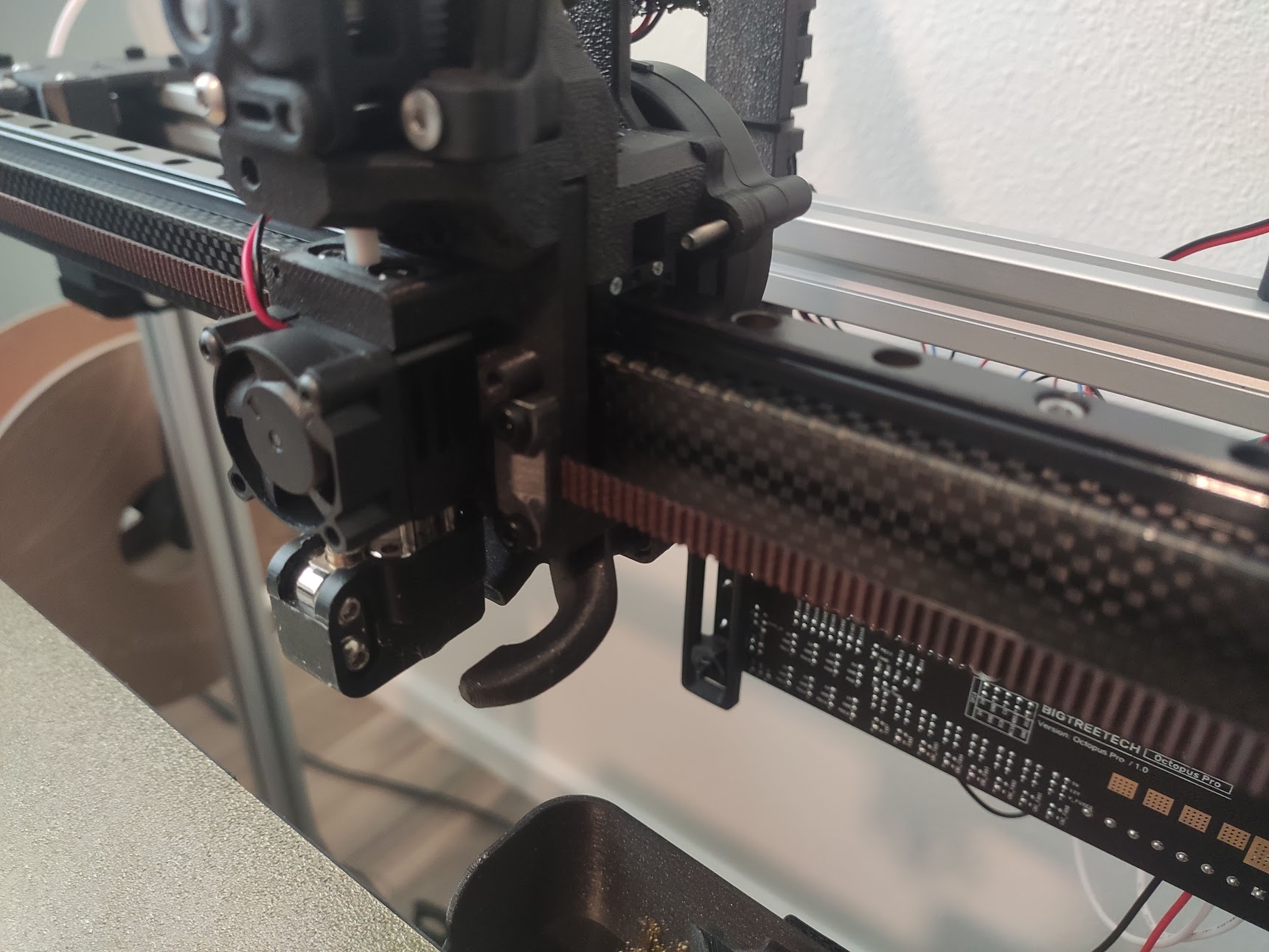

While Vzbot designs are still CoreXY, the design choices they made don't limit it nearly as hard as Voron designs. The toolhead sits on top of the rail, on top of the extrusion, and maintains a very stable center point without being heavy. Reduction of weight means that you will get higher accelerations before you get any ringing or ghosting. Vzbot also has great support for carbon fiber gantries, as well as machined aluminum gantries depending on your needs that weigh much less than 2020 extrusions, once again leading to more power to drive the print head, and less ringing.

Basic specs

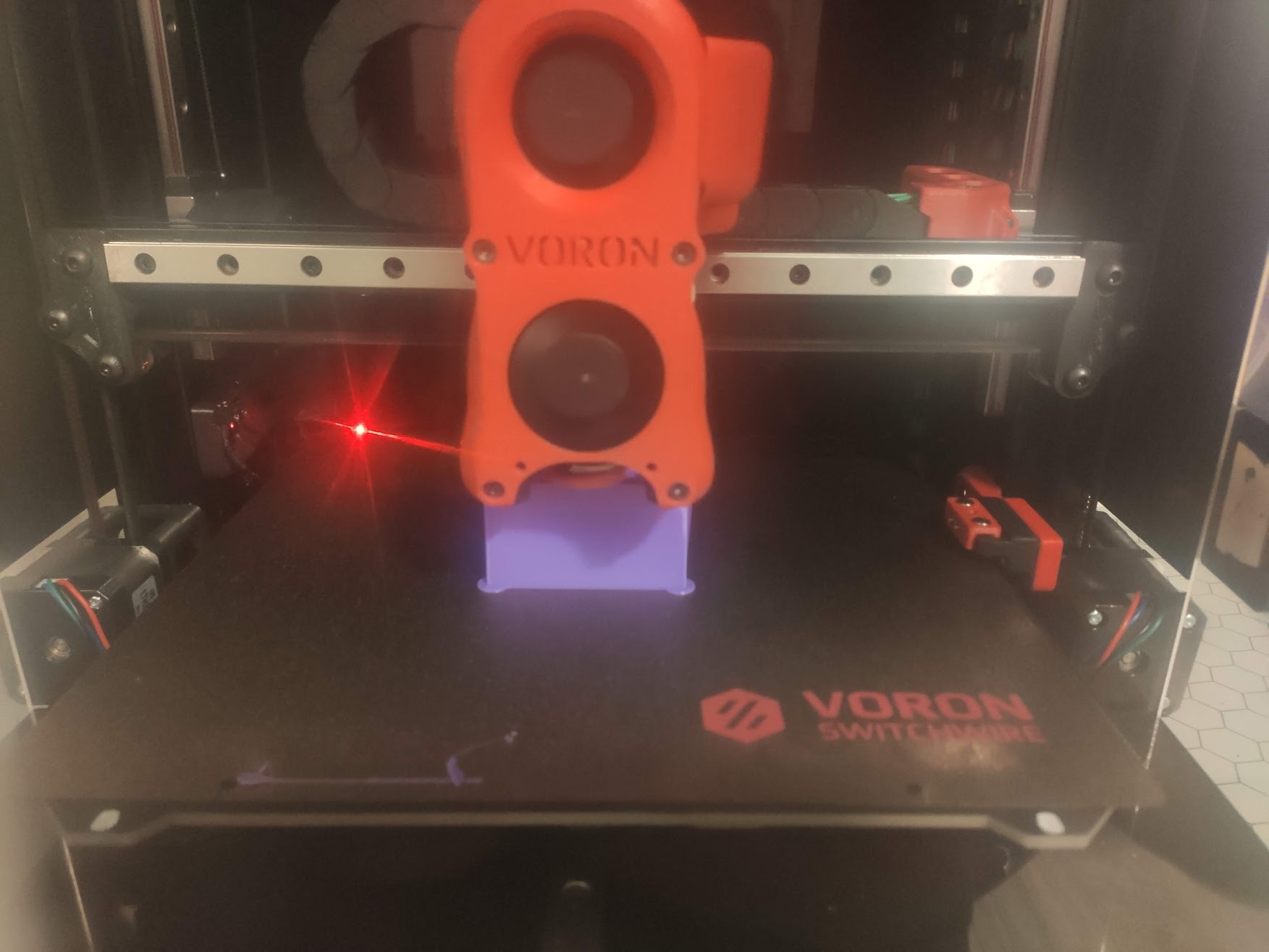

- NF Crazy hotend (Volcomosq Clone)

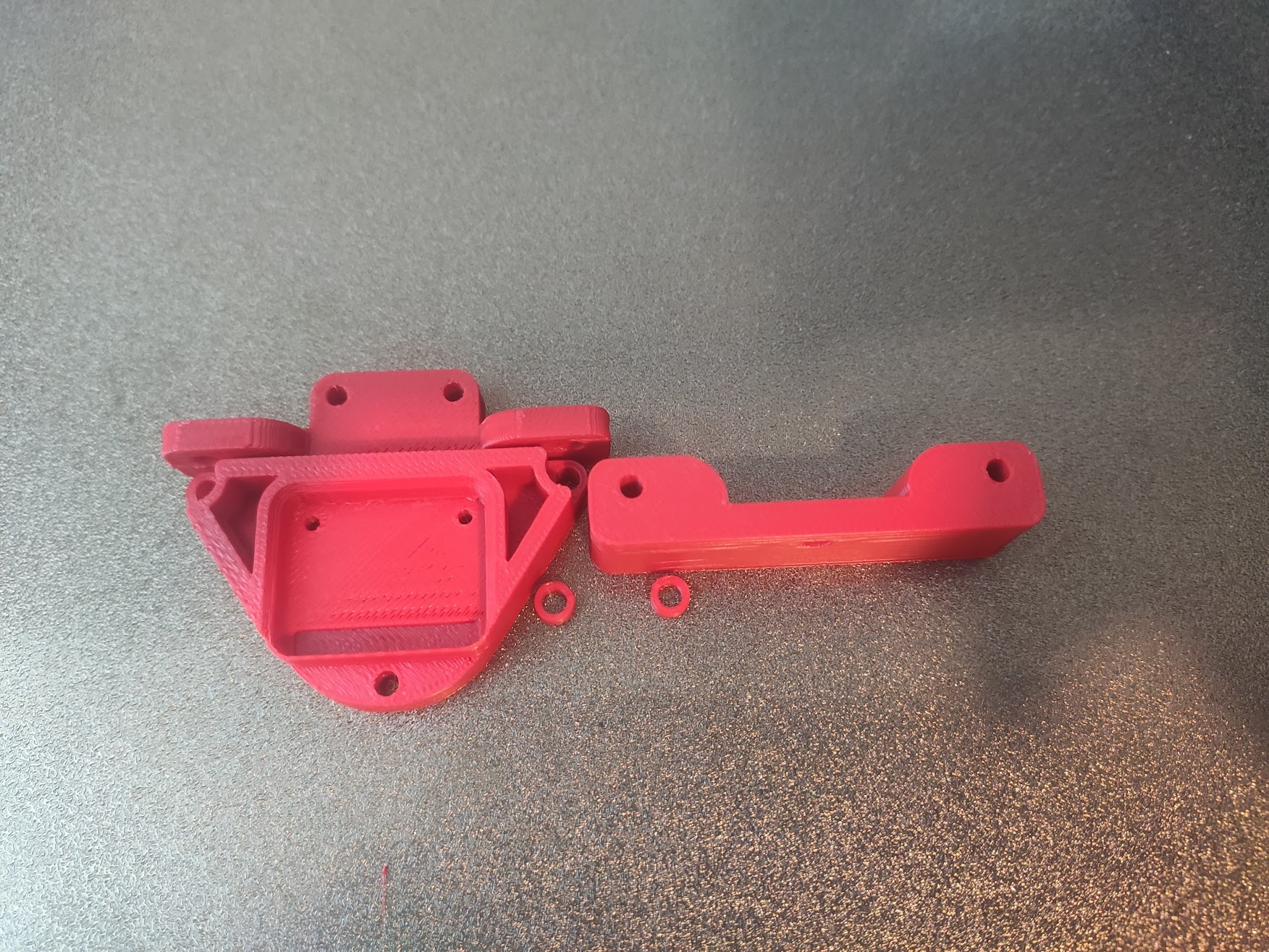

- Sherpa Mini extruder

- LDO Stepper Motor - Nema 17 - 42STH48-2504AC (A/B Motors)

- TMC2209 Stepper drivers (24v)

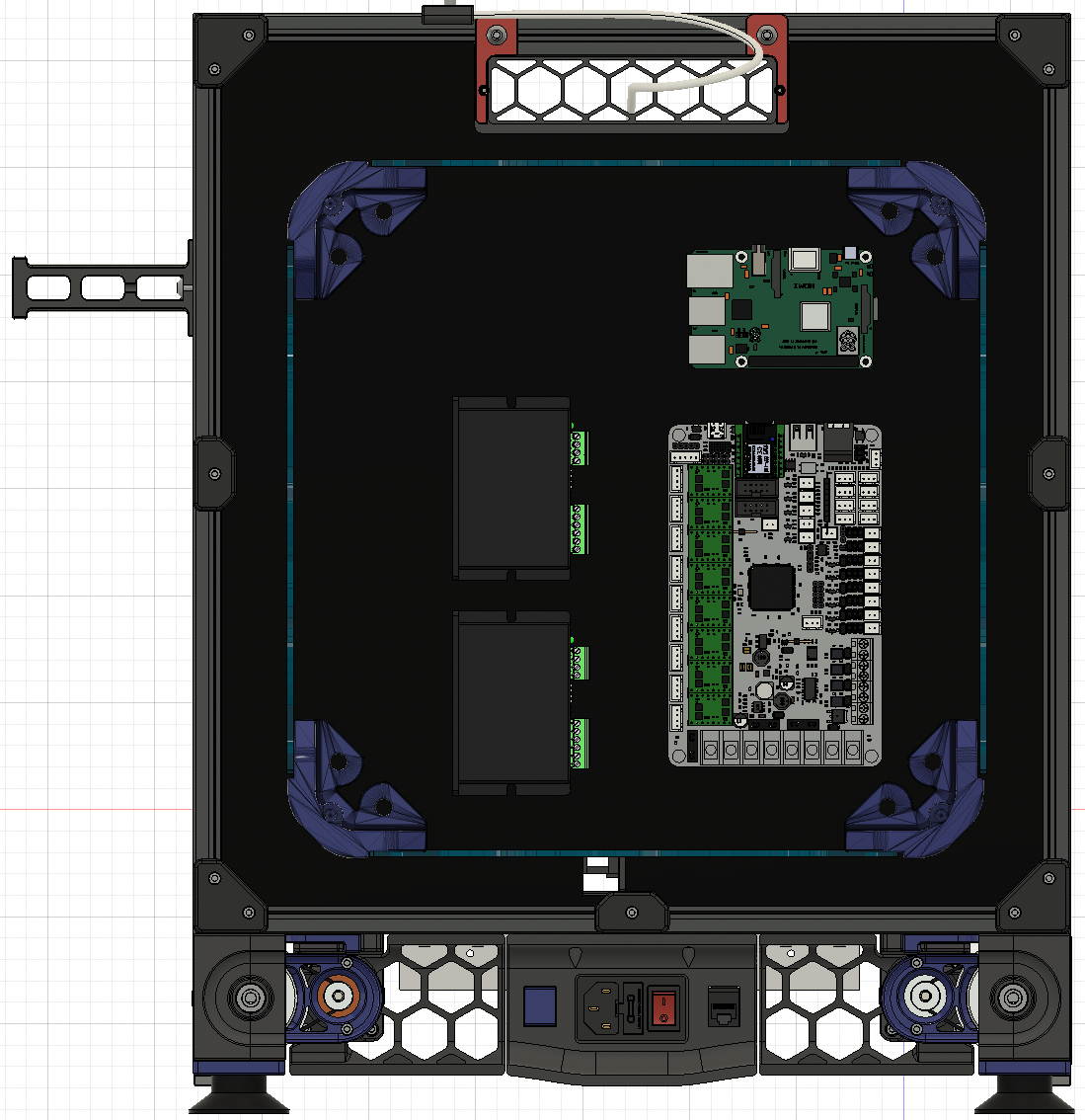

- Octopus Pro Mainboard

- Asus Chromebox (Klipper pi replacement)

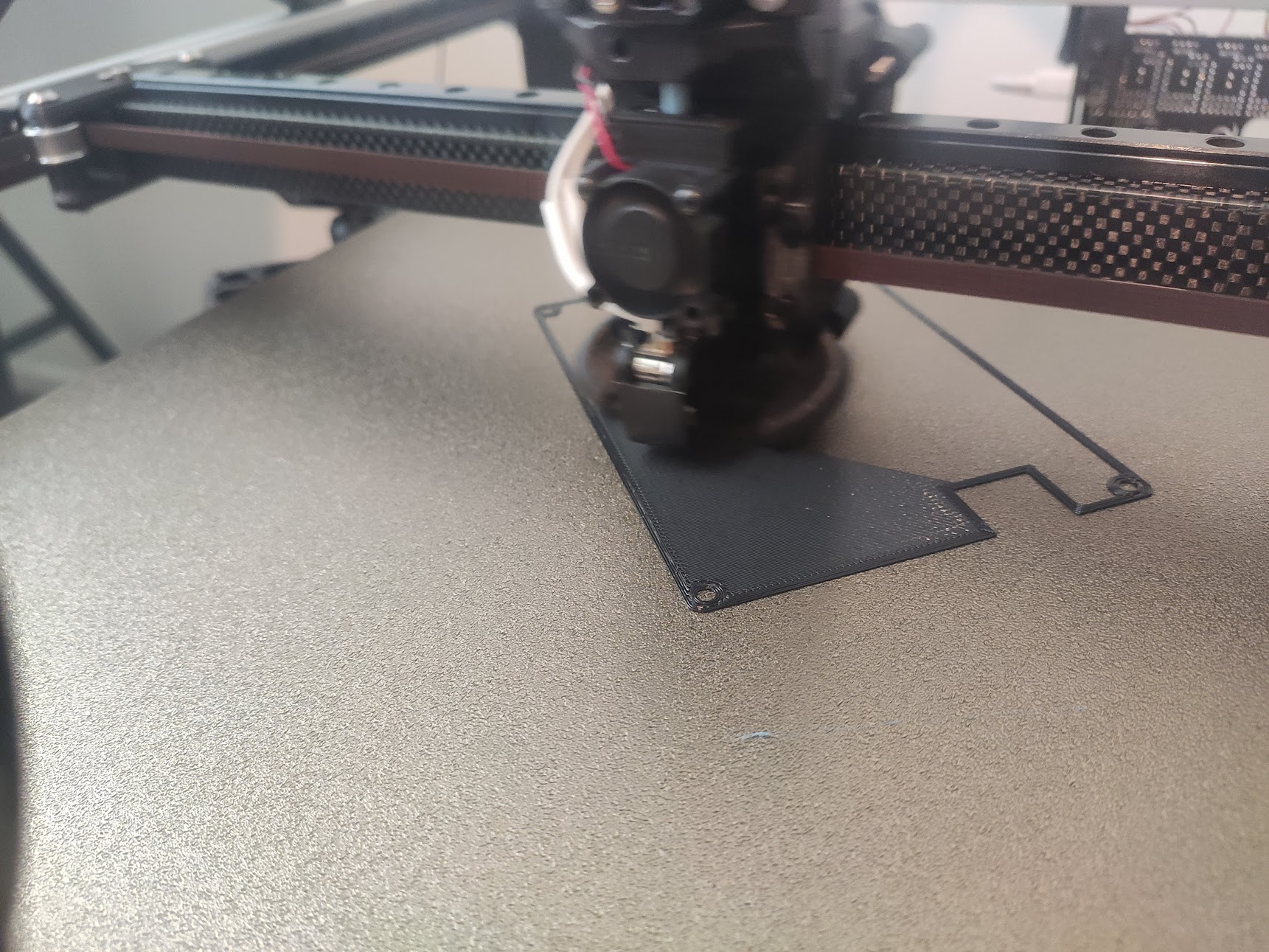

- No probe

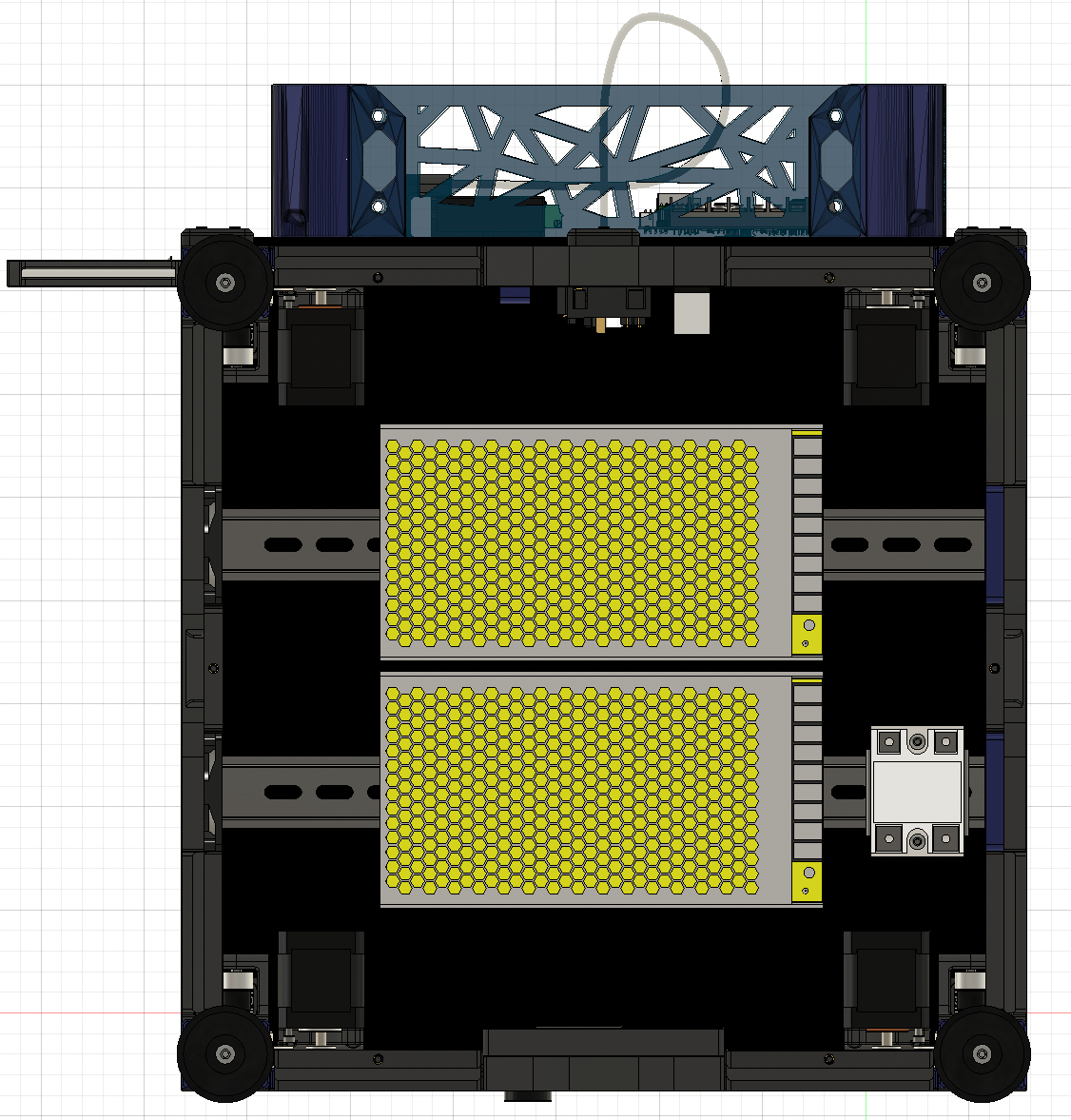

- F3D MIC6 Alu bed

- 120v AC heatbed

Part choice breakdown

I wanted a machine that was able to do at least 30mm^3/s, and the NF Crazy seemed like a good deal at only $65. When Vzbot parts were chosen, that was double that of the Switchwire, so nothing to sneeze at. The Octopus Pro mainboard is able to handle stepper drivers up to 60v, so that will allow for 48v stepper drivers to be used once they come back to markets as there is a part shortage at the moment. The TMC2209 drivers are only 24v, but they allow quite a high current as long as you have active cooling, and will do fine for the Z motor and extruder even longer term. As for the extruder, the sherpa mini was chosen due to it's high level of support on so many printers, Annex knows how to make amazing anything printer related, and it's light weight, so it fit right in. No probe and a single Z motor was a no brainer for me. No auto bed level when you can just never let it get out of level after initial calibration. F3D makes a very flat bed, so warping was not a concern, and I can just save all of that wasted probing time, and weight.

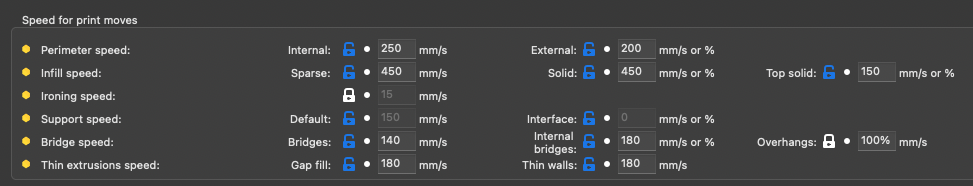

What kinds of speeds can it really hit though?

For accelerations, I'm running 10k accel, 10k decel on all visible features, and 15k/15k on features internal that won't be seen. Travels speeds are 1m/s 15k/15k accels.

This is substantially faster than Switchwire. That machines is limited to only 200mm/s and between 2k-10k accels, but most are closer to 2-5k. This reduces print times massively both on small and large objects thanks to the higher average flow rate.

Eventually

This machine is still not enclosed, so it will get more rigid over time, as well as just being able to print materials like ABS and ASA better in the hotter ambient temperatures. I'm quite happy with the speeds that I'm getting with only 24v, but eventually 48v is a must. Lower current for the same speeds if nothing else, which is better for the motors, especially once enclosed as the temps will creep up. I may add a few more things here and there as I need them, but it's all up in the air, and I'm enjoying the new toy at the moment. I'm sure eating through filament at a rate I've never seen before though.

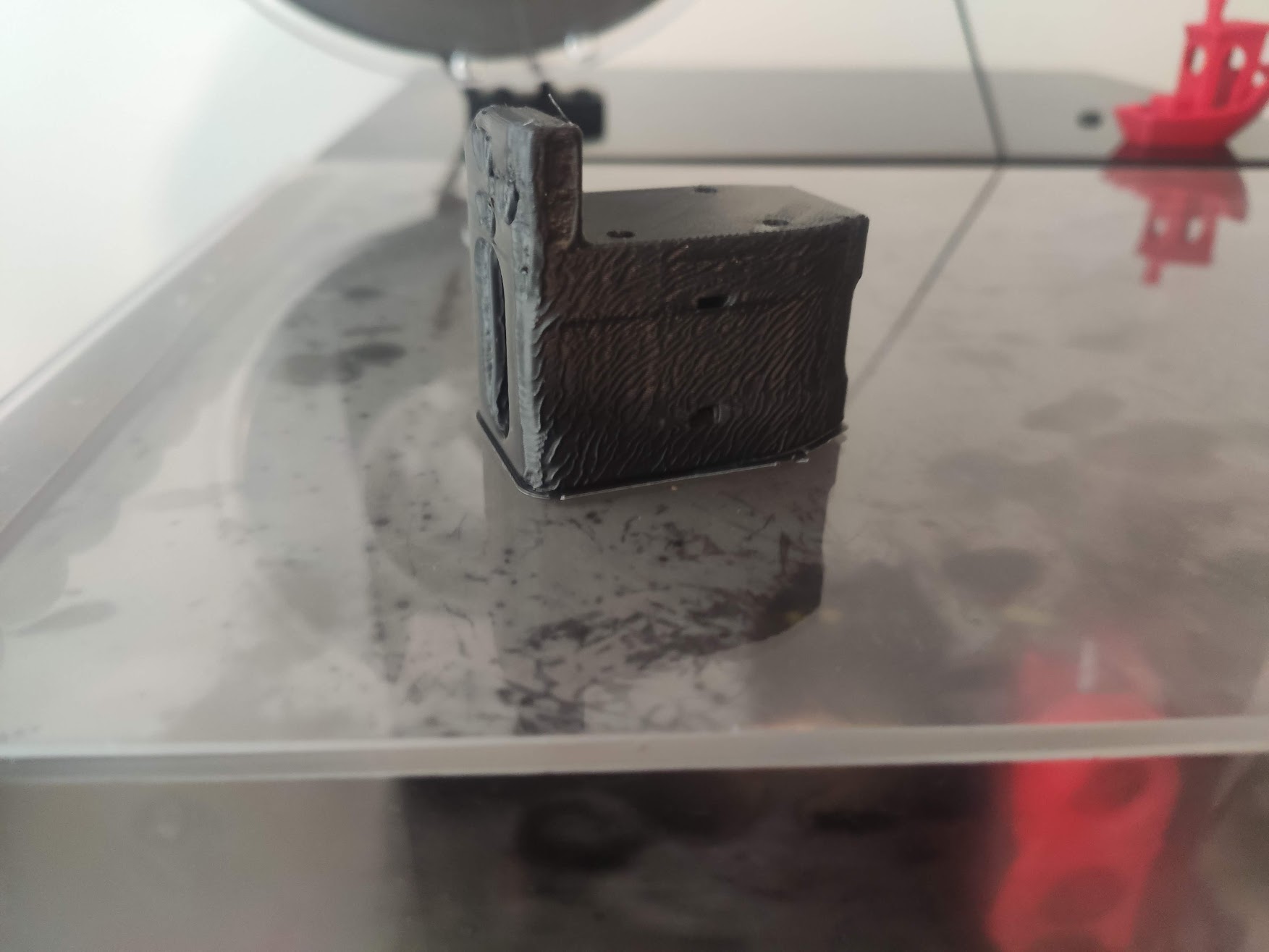

Some pictures