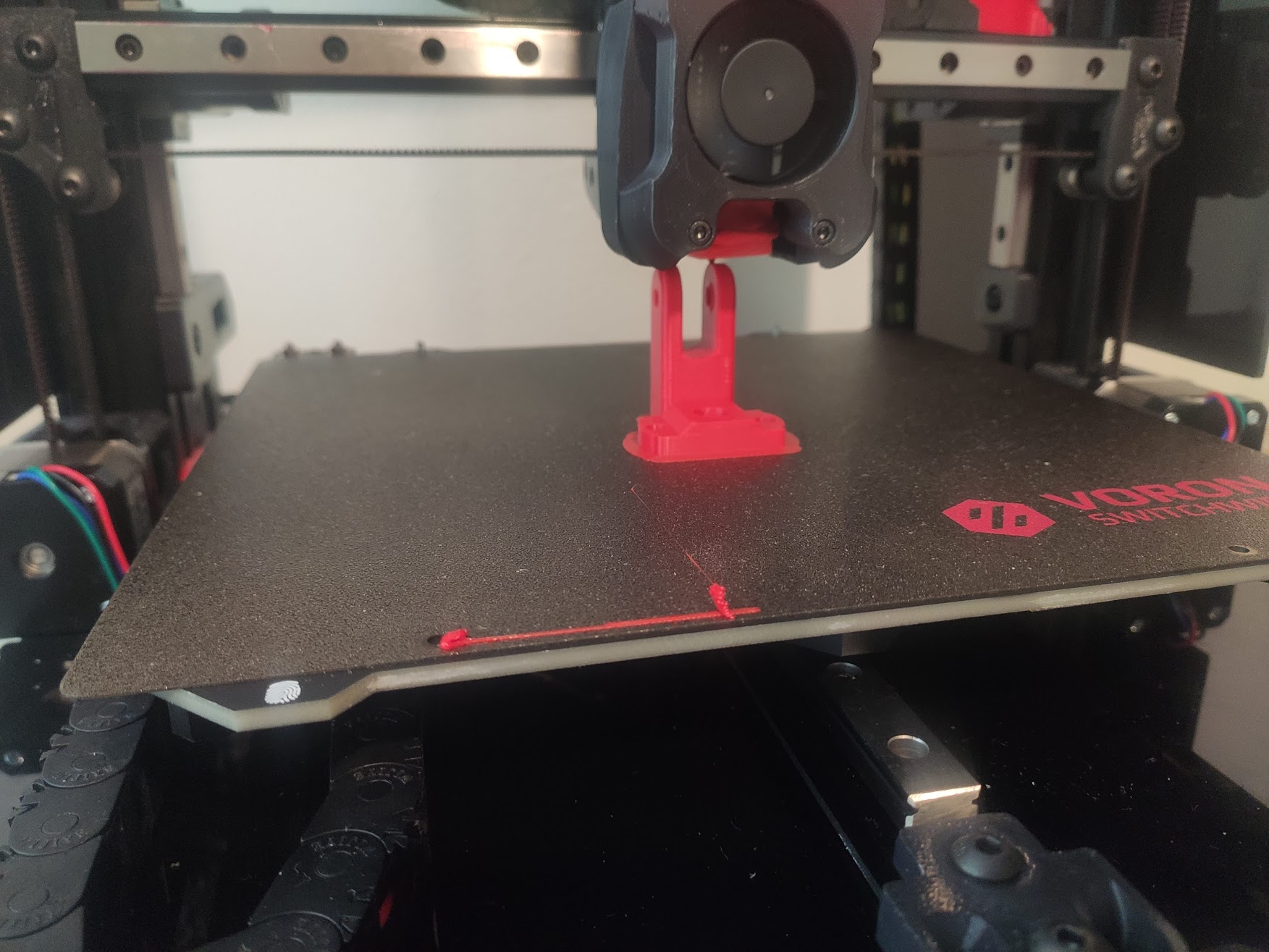

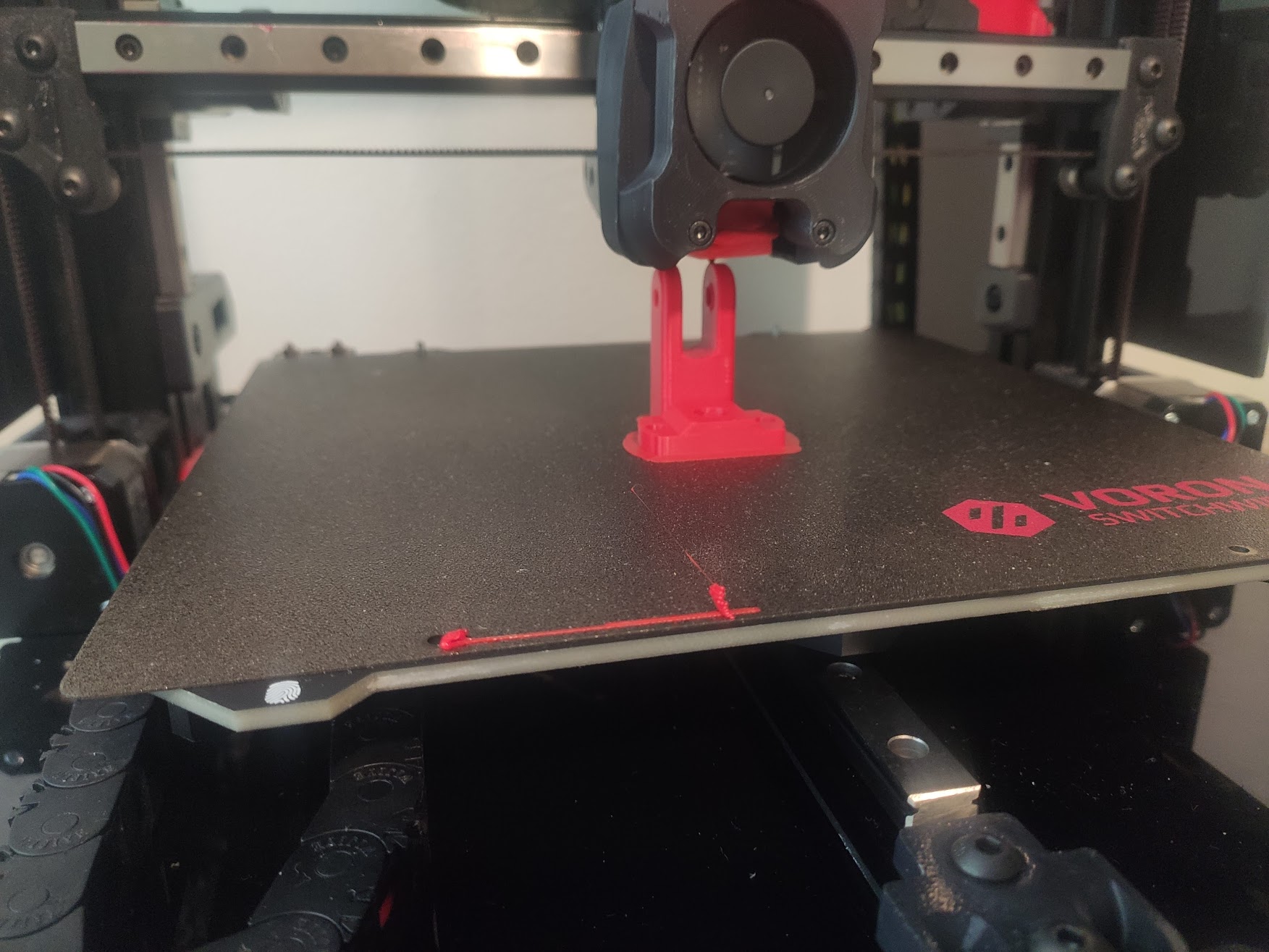

While my switchwire has been a lot of pain, and fun, but mostly pain, I'm back

at it. There's some things that I love, and hate about the switchwire, and while

I intend to still use it, I think it's time to build something that not only

addresses those problems, but goes faster. This is just a really rough writeup

of my thoughts that will change over time, but is here to keep track of what the

plans are, and how they change over time.

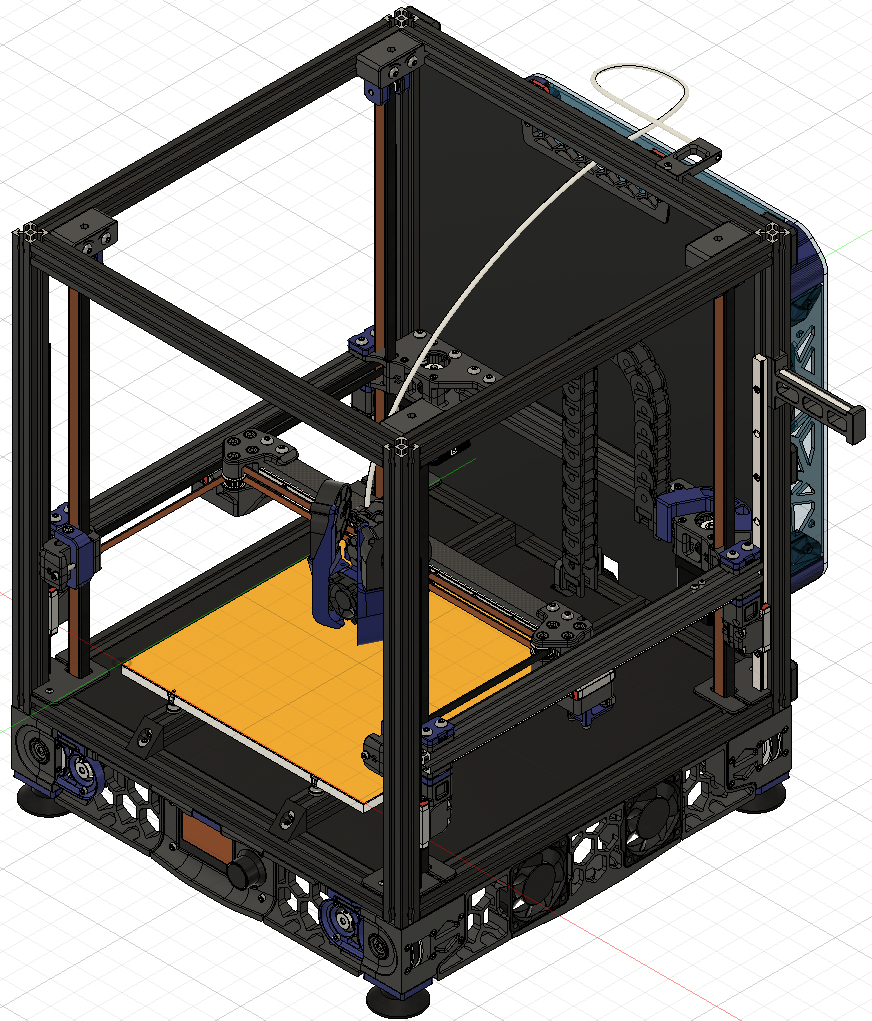

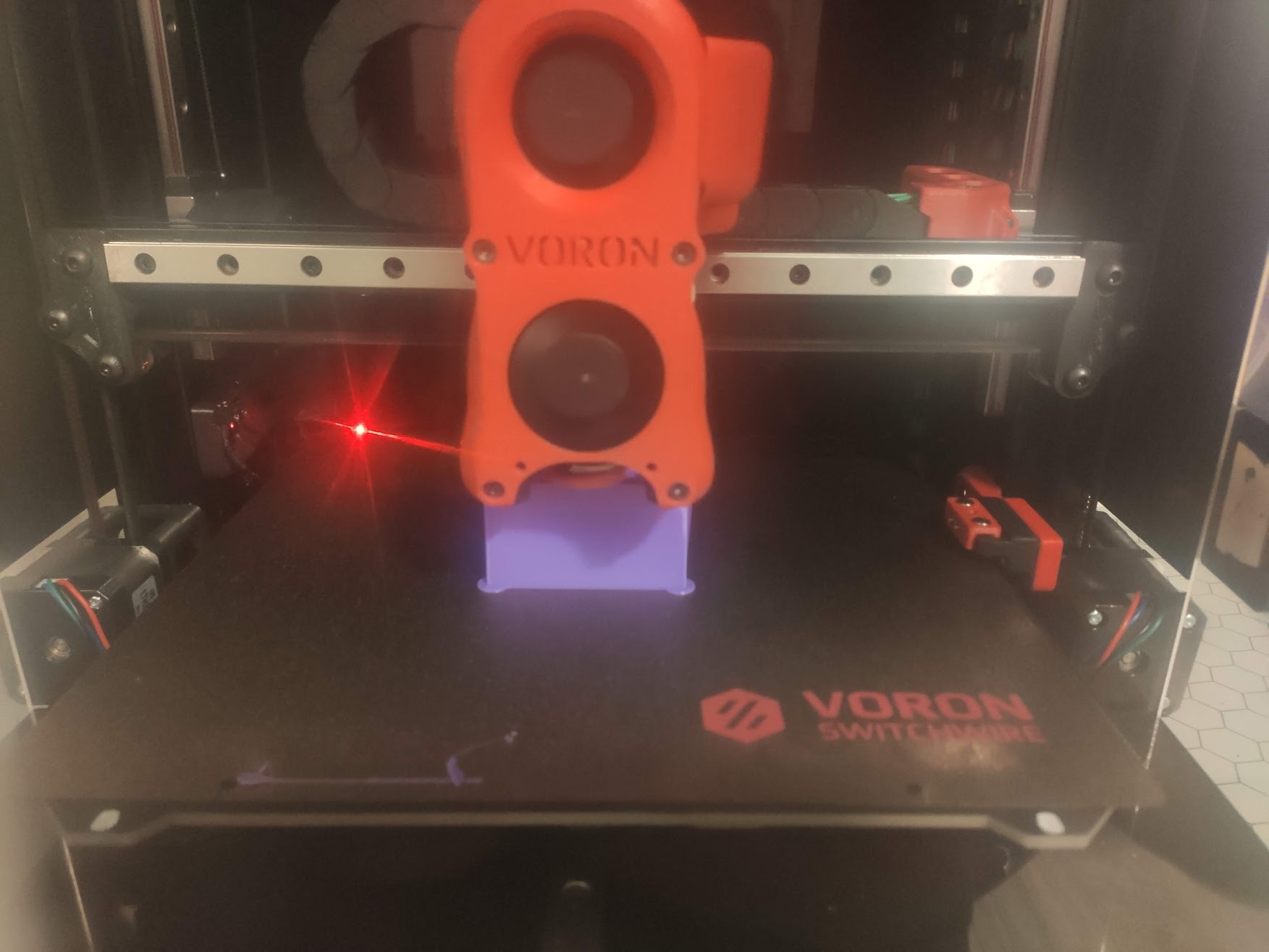

The current plan is to start with a Voron Trident kit from Formbot, similar to

where my Switchwire started from, and modify it to hell and back. The Trident is

a fixed gantry CoreXY printer, which is generally pretty fast, even compared to

my Switchwire already, but the need for speed is a thing. Mods will be broken

down into 4 categories. QOL, Speed, Quality, and Eventually.

180 degree

hinge

allows the doors to completely open. Not needed, but sure nice to have.

Sexbolt

is one of the biggest QQL mods. This allows for nozzle to probe auto

calibration, making things a lot more reliable, especially when thermal

expansion starts to kick in.

Klicky

probe

allows for probing of not just metal sheets, but any material you could want to

print on, and will pick of thickness changes, making this and the nozzle offset

auto calibration some massively useful QOL. It also makes the gantry lighter.

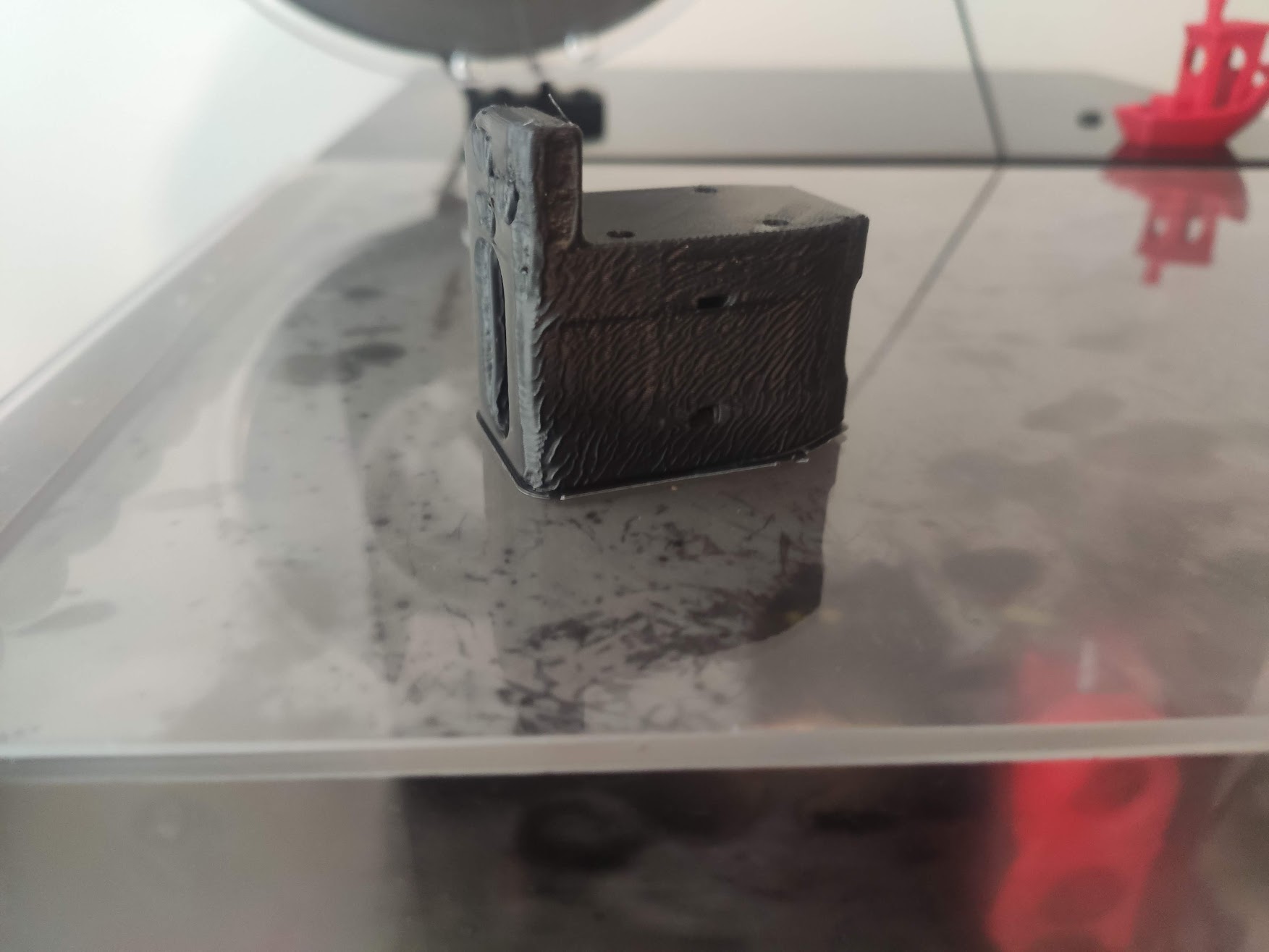

Pins

mod

will actually be done with carbon rods for a lighter gantry,

but also increases the print quality by preventing any catching on the threads

that are normally used as pins on a stock gantry.

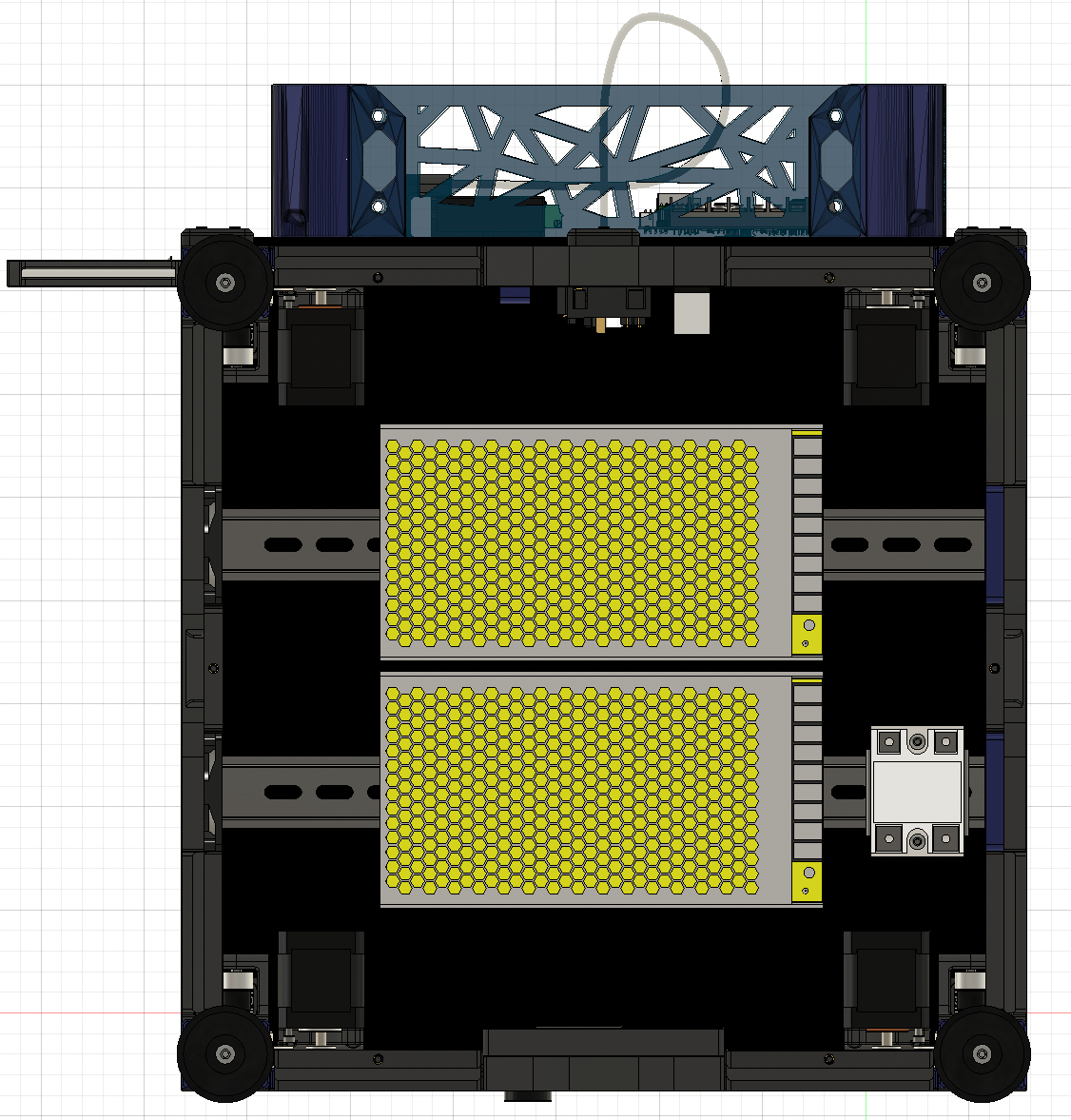

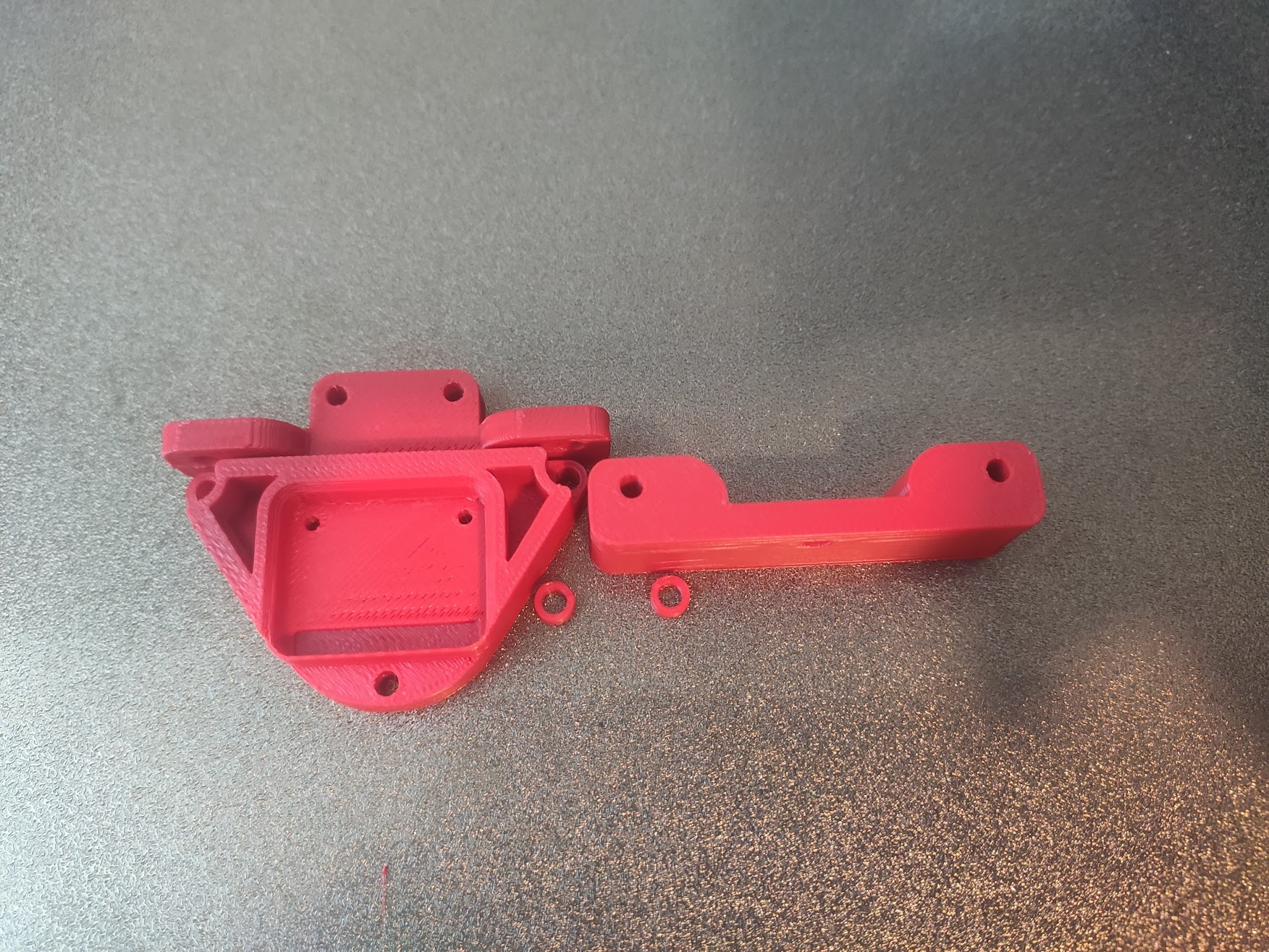

Mantis

toolhead

is designed to add two 5015 fans to the toolhead for much better cooling,

reduces weight, adds a sherpa mini extruder for more power and weight reduction,

and supports insane hotends like the Volcano Dragon hotend, that adds volcano

nozzles to the already high flow dragon hotend.

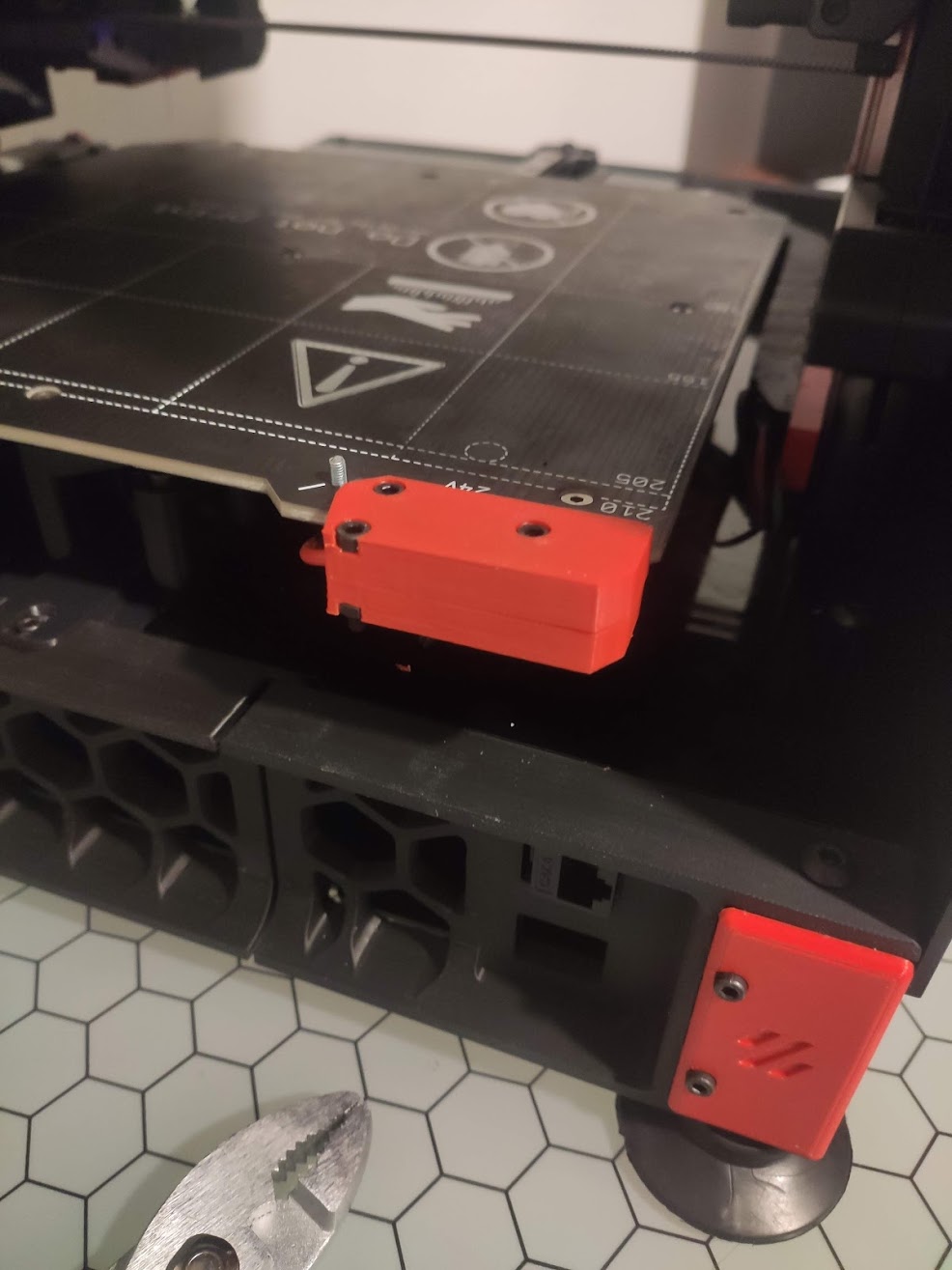

Endstop

relocation

goes along with the Mantis toolhead to add the endstop back.

Ramalama

idlers add

back most of the build space that was removed due to the difference in shape of

the Mantis toolhead, as well as making them stiffer, which should help with resonance.

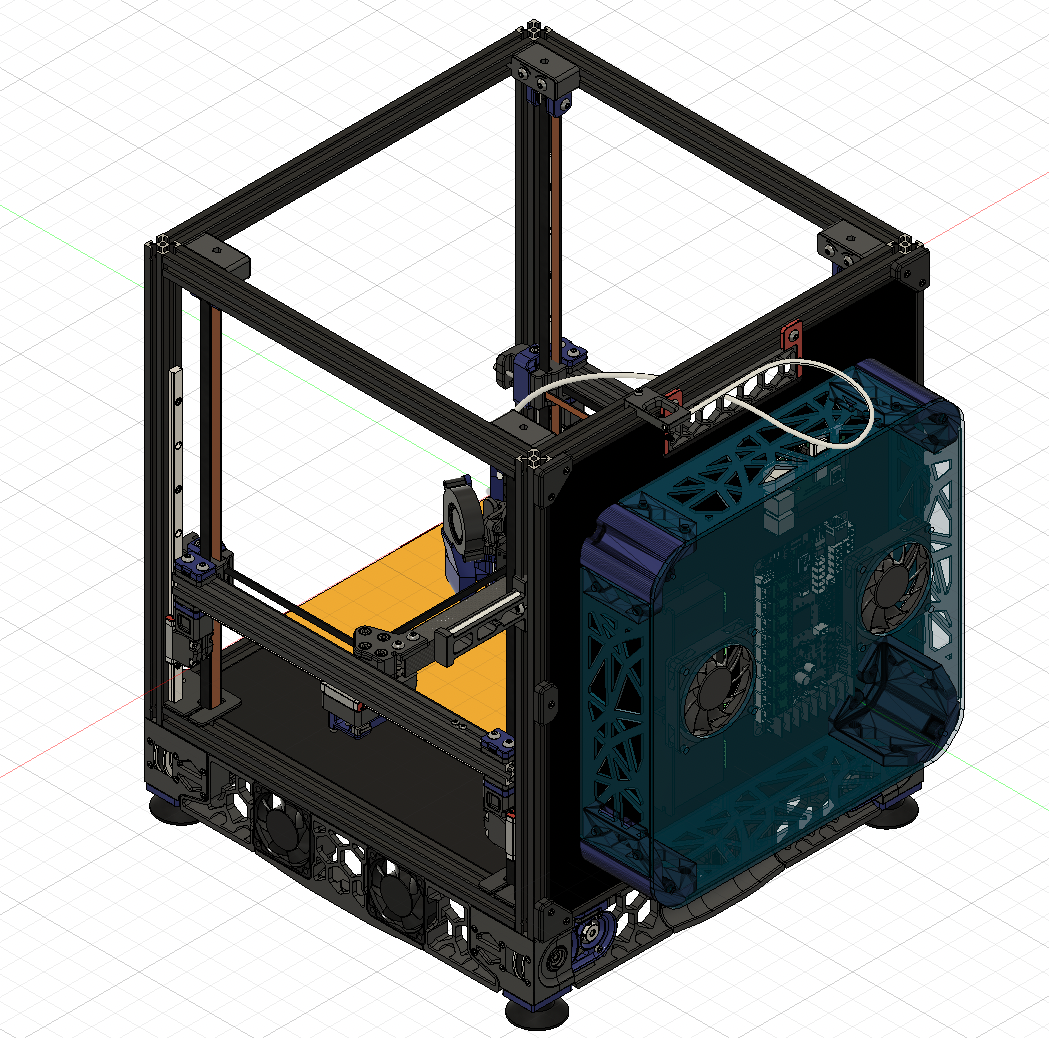

Carbon fiber gantry, to

replace the 2020 extrusion. This saves massive weight, not only helping the

motors not skip steps, but helping immensely with resonance at higher

accelerations. This will allow for much higher input shaper tolerance of high

acceleration, and should at least get to 25k accel without any noticeable

smoothing due to input shaper.

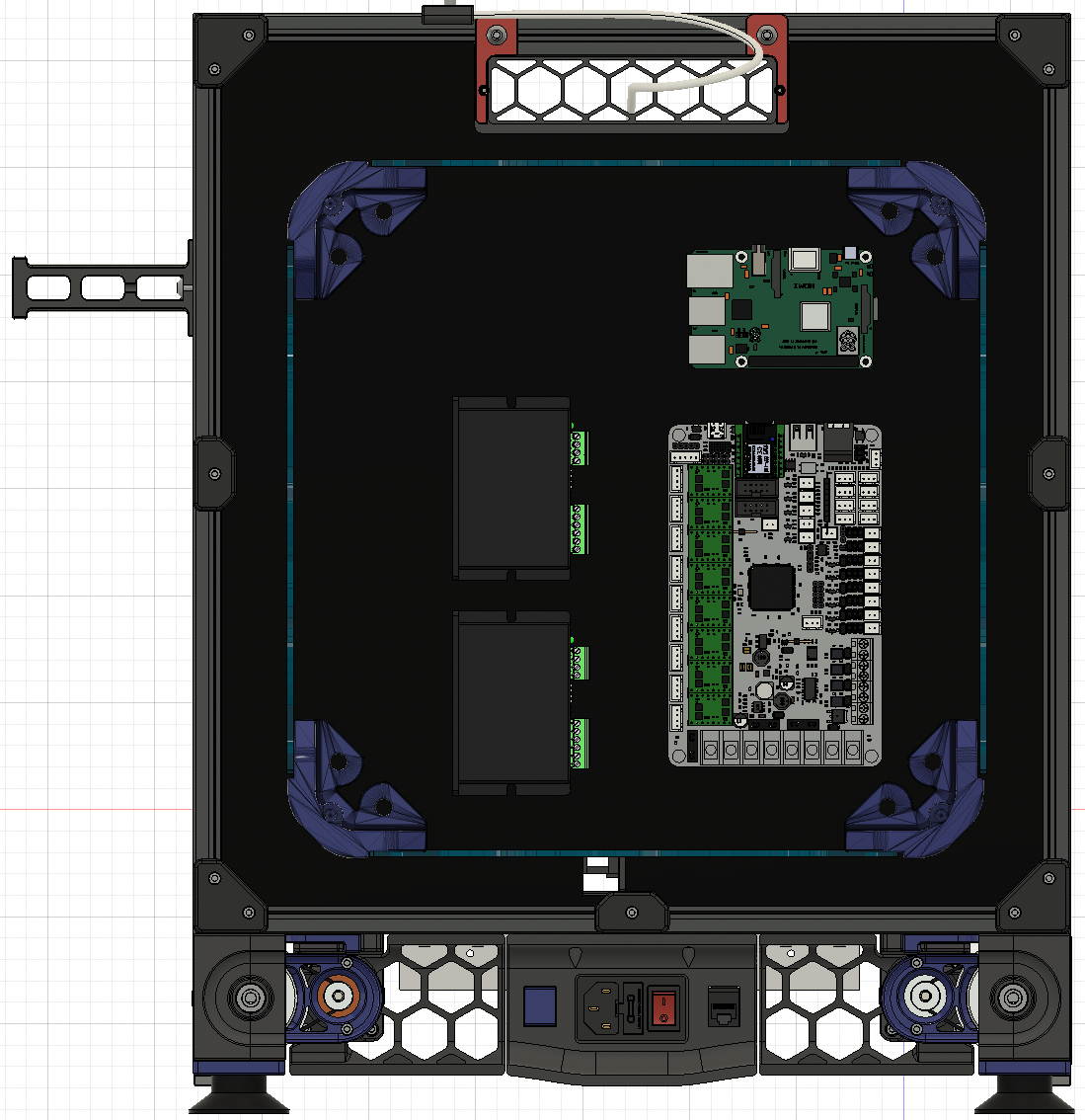

48v motors are on the table for one day, but due to the chip shortage, there are

absolutely no driver boards to be found in stock, even from AliExpress. There

are several options on the table in terms of driver boards, to motors, to

controller boards to house the drivers, but it will come down to what I can

source, as opposed to what I want.

This project has been started in a sense. I've ordered the carbon rods, carbon

fiber shaft, and a sherpa mini with some other small things on the slow boat,

but the core printer isn't set in stone. I'm looking to iterate on ideas and

change my mind, but I'm taking quite a lot of tips from the Annex engineering,

HevORT, and VZbot teams. We'll see what else helps push this printer to go fast,

but also be reliable, as far as what a 3d printer really can call reliable.